Aerospace

Aerospace - on-demand rapid manufacturing

Our reliable rapid prototyping services have provided processing services to many clients representing different stages of the aerospace industry. We continuously expand our production capacity and introduce high-end processing and testing equipment to ensure that we can meet customers' demands for high quality and delivery time. We can meet customers' needs from 1 piece to small or large batch production of parts, and the most important aspect is that our quality standards are very high. We can quickly manufacture aviation components for customers to verify and test, and then customers can decide whether to optimize the design.

What problems has YYI TECH solved in the field of Aerospace manufacturing?

● Forming complex parts

It can handle various metal forming techniques to manufacture parts with complex geometries and different thicknesses. This multifunctionality is crucial in aerospace manufacturing, as parts typically require complex shapes and structures to achieve specific functions. In addition, the advancement of RP technology has made the production of parts more complex, further expanding the application scope in the aerospace field.

● Model

RP technology can transform design ideas into product prototypes with certain structural functions at the fastest speed, transforming design models from "visible" (3D digital models) to "tangible" (solid models). Therefore, RP technology can quickly obtain conceptual products, focusing on the restoration of appearance and display effects. It is usually used for sales demonstrations and market promotion of new products, testing market reactions, and thus improving the market response speed of new product development: reducing development risks.

● Prototype

The rapid prototyping obtained using RP technology can fully evaluate the assembly and manufacturability of the product. Due to the high degree of integration of CAD/CAM in RP technology, it can not only quickly restore the appearance of products, but also quickly produce product parts and structural components, thus enabling verification and analysis of product structure and assembly, rapid evaluation and testing of product design, shortening the development cycle of product development, reducing development costs, and improving the ability to participate in market competition.

● Unit manufacturing,direct production in small batches

By using indirect molding methods and combining various conversion techniques, RP prototypes can be converted into various rapid molds, such as silicone mold technology, RIM technology, simple injection molds, etc., which can conveniently achieve single piece or small batch product production and satisfy the development trend of fast product updates and small batch sizes,

Application of rapid prototyping in Aerospace industry

Aerospace products have the characteristics of complex appearance, small batch size, large differences in part specifications, and high reliability requirements. The shaping of products is a complex and precise process that often requires multiple designs, tests, and improvements, which is costly and time-consuming. RP technology has unique application prospects in the research and development of modern aerospace products due to its agile and diverse process methods and technological advantages.

■ Structural components

■ Body panel

■ Wing ribs and struts

■ Landing gear components

■ Engine components

■ Turbine blade

■ combustion chamber

■ Exhaust nozzle

■ Instrumentation and control panel

■ Switches and buttons

■ Connector components

■ Seat frame

■ Cargo hold components

■ Body components

Vacuum casting Nylon UAV

● Customer requirements:

30 sets of plastic casings for drones, needs to conduct flight tests, requiring materials with high strength, not easily broken, and surface treated with spray paint

● Production difficulties:

Small quantity, thin wall thickness, difficult to control deformation and dimensional accuracy

● Quantity: 30sets

● Material: Nylon

● Process: Vacuum casting process

● Delivery time: 15days

Our Production solution:

According to customer needs, we recommend vacuum casting technology for production, And recommend nylon material, balancing lightweight and high-strength requirements. ,and for deformation and dimensional accuracy issues, we have made correction fixtures for post shaping and correction treatment. The product surface has been polished and painted to achieve smooth surface.

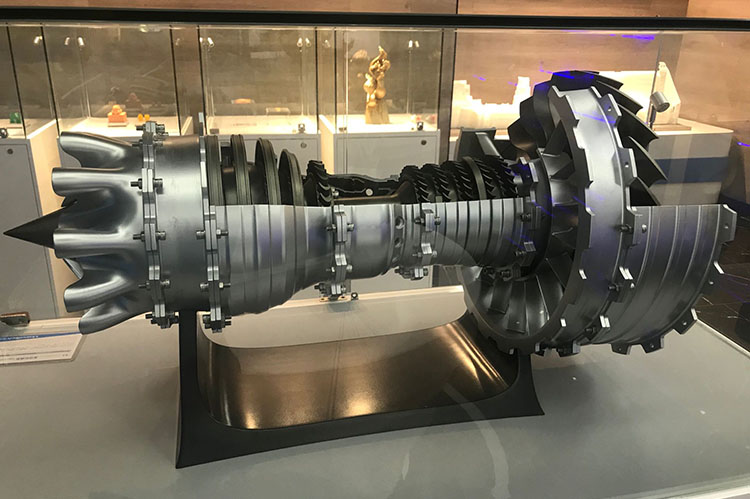

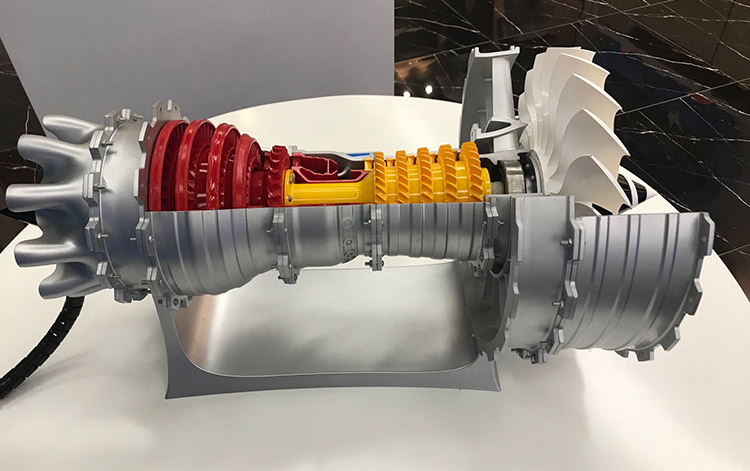

SLA Resin + SLM Metal 3D Printed Rocket Engine Model

● Customer requirements:

Need 1:20 rocket engine display model, with surface parts made of metal and internal materials not limited.Partial dissection is required to reveal the internal structure

● Production difficulties:

The parts quantity is large, structure is complex, and the assembly difficulty is high

● Quantity: 1set

● Material: Resin+aluminum

● Process: SLA+SLM 3D printing process

● Delivery time: 10days

Our Production solution:

The outer shell of the parts adopt SLM aluminum alloy 3D printing, and the interior adopt RESIN material to reduce costs. During the assembly process, there may be individual part size deviations and deformations, which make it impossible to assemble. Each part needs to be manually repaired before final assembly