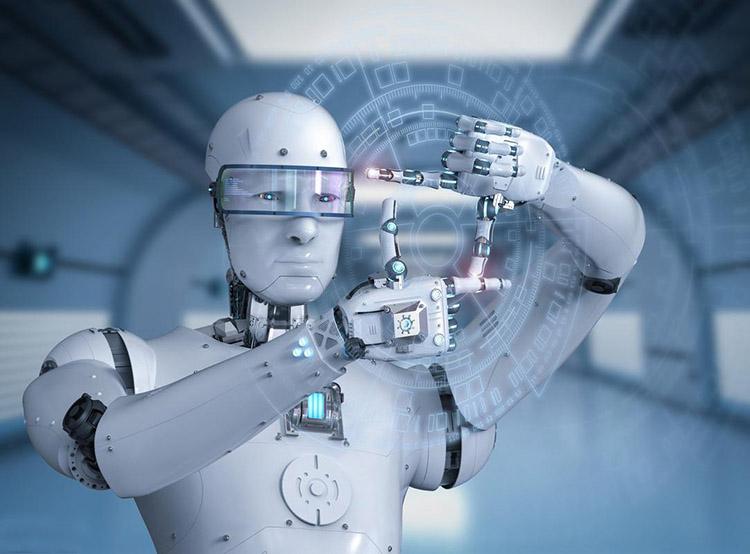

Artificial Intelligence(AI)

Artificial Intelligence(AI) - On demand rapid manufacturing

One development direction for robots and precision machinery is biomimetic, which involves evaluating and verifying the precise assembly design of a large number of motion components before freezing, soliciting user opinions, and producing in small batches.

YYI TECH can flexibly use various rapid prototyping processes, allowing you to achieve design freedom,quickly complete the production of customized parts, engineers can accelerate the research and design stages, thereby enabling new, higher quality robots to be put into use faster.

What needs has YYI TECH solved in the Artificial Intelligence manufacturing field?

● Small scale mass production

No need to mold, shorten production cycle, reduce production costs, and accelerate the time for product launch into the market.

● Personalized flexible manufacturing

The personalized demand for artificial intelligence products is increasing day by day, and these intelligent products require precise 3D data as support. Tailored flexible production methods will become a necessary condition for intelligent hardware to meet customer needs.

● Interaction Design

Based on precise personalized data collection, our technical team will provide customers with rational suggestions for product design, utilizing our rich experience in the field of intelligent hardware to provide customers with optimized and achievable solutions.

● Test validation

By providing customers with efficient and low-cost test samples through rapid prototyping, we can quickly verify design solutions, reduce trial and error costs, and promote continuous iteration and upgrading of research and development.

Rapid prototyping design and development of new industrial robots

The combination of rapid prototyping and industrial robots is seen as a solution to meet the growing demand, where manufacturers must manufacture large objects in large quantities and with precision, while also hoping to achieve automation in the production process. With the development of rapid prototyping technology, their integration with industrial robots has become increasingly simple, giving rise to the concept of intelligent manufacturing

When manufacturers need to produce products accurately, quickly, and in low batches, YYI TECH can often flexibly combine various processes in rapid prototyping to assist in prototype design, quickly complete the production of customized parts, and help the industrial field develop better and more efficient robots. Engineers can accelerate the research and design stages, enabling new, higher quality robots to be put into use faster.

Rapid prototyping application in Artificial Intelligence(AI)

The flexible application of various processes in rapid prototyping can accelerate the innovative development of artificial intelligence products and better achieve the goals of artificial intelligence:

■ Intelligent robot development;

■ Inspection tools and fixtures for intelligent production lines;

■ Remote medical preoperative model;

■ Direct printing of core circuits, etc.

Classic case we have done

SLA 3D printing Resin Robot appearance display piece

● Customer requirements:

Need to make a robot for external display in the exhibition hall, with movable arms, head, and base, and the appearance needs to be consistent with the finished product

● Production difficulties:

Nearly 100pcs parts, which require good control accuracy and deformation to be assembled properly. Surface requirements is high, easy to produce defective products, requiring multiple rework.

● Quantity: 1set

● Material: Resin

● Process: SLA 3D printing process+surface treatment

● Delivery time: 15days

Our Production solution:

(1) A robot with hundreds of parts, considering budget and delivery time, recommended 3D printing with resin material,which can create a beautiful appearance in a short period of time

(2) The appearance needs to be smooth and flawless, using surface polishing+painting+UV+

silk screen

SLM metal 3d printing industrial gear

● Customer requirements:

Produce metal gear samples for functional verification

● Production difficulties:

Difficulty in controlling dimensional accuracy and surface roughness

● Quantity: 5sets

● Material: Stainless steel 316L

● Process: SLM 3D printing

● Delivery time: 5days

Our Production solution:

1. The parts need to undergo functional verification, which requires the accuracy of the product. Based on this, we will increase the fit clearance between the male and female gears to meet the verification requirements after assembly

2. In response to surface roughness, we have ground the parts to meet their basic surface requirements

Significant savings in sample production time and cost for customers