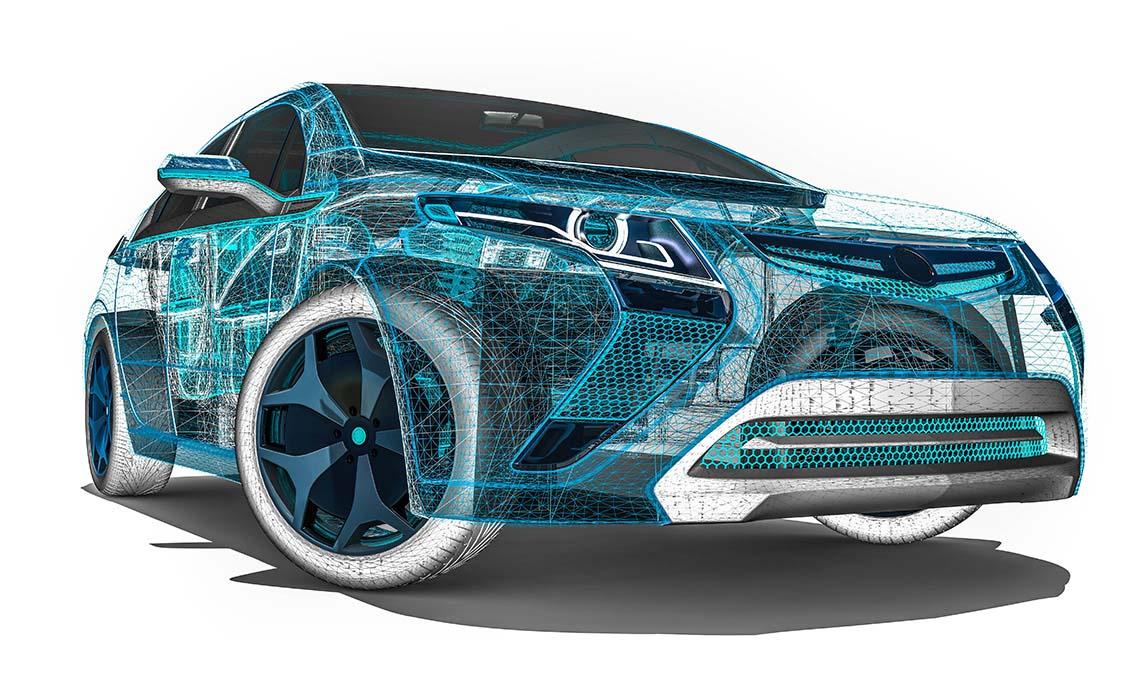

Automotive

Automotive - On demand rapid manufacturing

Driven by consumers' demand for fast, safe, comfortable, and trendy cars, cars are constantly being updated and upgraded. For example, the development cycle of a new car used to be five years, but now car manufacturers have shortened this time to three years, and the daily cycle continues to shorten. The R&D cycle of various products has been applied, which can shorten the development cycle by 80%, save more than half of the cost, and significantly improve product quality.

YYI TECH Prototype Factory integrates various rapid prototyping processes to provide the best production solutions. It not only produces many automotive component prototypes and small batches, but also offers 1:1 whole vehicle production, meeting the needs of car manufacturers to accelerate the upgrading of automobiles

What problems has YYI TECH solved for customers in the field of automotive manufacturing?

● Prototyping

Complete materials, supporting processes, and sufficient production capacity ensure that we have the ability to provide you with the fastest design verification and prototype delivery.

● Small batch production

Small batch production not only saves you production costs caused by large-scale production, but also saves you time in launching products to the market. It opens up a new sales model for you, allowing you to grasp market feedback on products in the shortest possible time and provide assistance in formulating product strategies.

● Comprehensive solution

As a one-stop service platform that integrates the industry's top technology resources, material resources, and technical talent resources, Bering 3D provides customized comprehensive solutions for you, pursuing the ultimate of products.

● Interaction Design Analysis

Based on each customer's needs and the characteristics of 3D printing technology, our technical team will conduct data analysis on customer requirements, provide professional technical support and modification suggestions, and ensure the accuracy and optimal cost-effectiveness of delivered products.

● Timely delivery guarantee

Adequate production capacity, full tracking of order delivery, and the ability to quickly solve problems are the guarantees we make for timely delivery commitments to you.

● Reverse engineering and after-sales service

Old car repair without accessories! Leave it to us, and we will print brand new accessories specifically for you without drawings or molds.

Rapid prototyping application in automobiles industry

■ Design, modification, and assembly testing of automobiles exterior and interior components

■ Trial production of engine and cylinder head

■ Powertrain

■ Chassis system

■ Car dashboard

■ Front and rear bumpers

■ Car air conditioning

■ Headlights

■ Doors and protective panels

■ Air intake panels

■ Air ducts and outlets

■ CCB brackets

■ Other car components

Classic case we have done

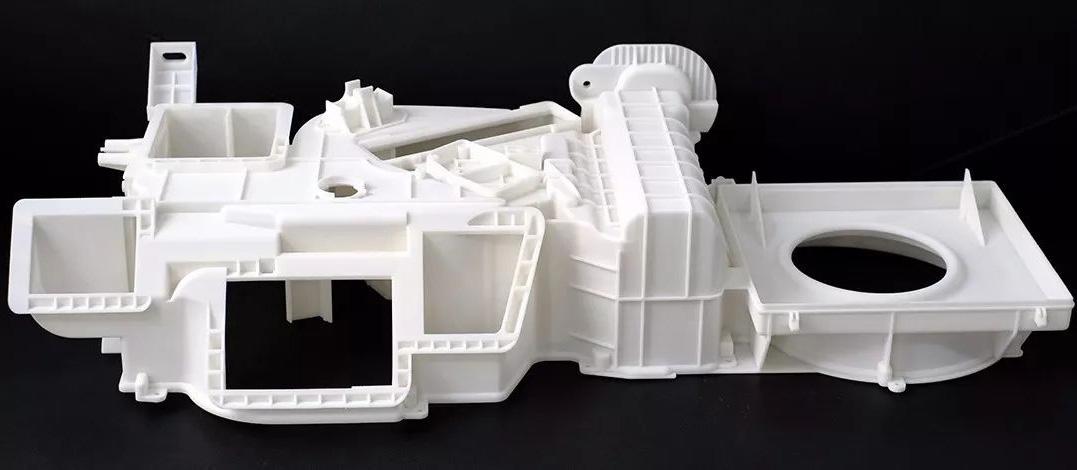

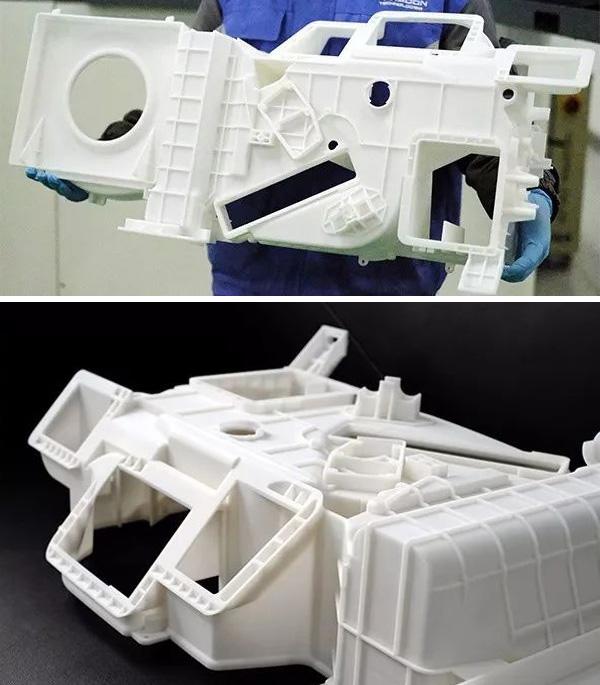

3D printing automotive air conditioning

Integrated molding of large and complex HVAC components, with superior precision and strength

HVAC air conditioning is a unit installed under the dashboard of a car with heating, ventilation, and air conditioning functions, including the blower assembly, heater core, evaporator core, mixing damper, mode damper, and other main components.

Adopting SLS nylon 3D printing integrated molding production, the structural strength is higher and the size is more accurate than CNC disassembly process.

The plastic shell and air duct of automotive air conditioning HVAC are relatively large plastic components in the interior of the car body. They play a role in carrying or assembling other components, and have strict requirements for their strength, impact resistance, high temperature resistance, and corrosion resistance. They are important components in HVAC. The design and manufacturing of HVAC assemblies must meet the following technical requirements:

■ Continuous temperature resistance performance: -40 ℃~+120 ℃;

■ The tensile strength of the shell material is greater than 55MPa, and the Young's modulus is greater than 3500MPa;

■ It needs to be formed as a whole with minimal shrinkage deformation;

■ High dimensional accuracy is required, with some dimensions having an accuracy of ± 0.1mm and a total length error of less than 0.3mm;

■ The material has flame retardant requirements, with a flame retardant rating of UL94-V0.

The total length of the HVAC housing exceeds 950mm and has a very complex structure. It is made by SLS nylon 3D printing integrated molding, which has higher structural strength, more accurate dimensions, and smaller deformation than CNC disassembly technology; Compared to the overall molding process of silicone molds, products made using SLS 3D printing are easier to control in terms of wall thickness and structural dimensions. Their structural strength is high and can be easily disassembled and assembled, making them suitable for sample vehicles, preliminary design verification, and data collection. This saves time on mold making, welding fixture production, and accelerates the early development process of automobiles.

Compared with traditional techniques, processing a car air conditioning HVAC housing only takes 2 days for 1 SLS 3D printer, 3 days for 2 CNC machines, and 5 days for silicone mold processing, bringing higher efficiency to industrial customers!

Reaction Injection Moulding RIM plastic Car bumper

● Requirement:

Need to make car bumpers for modified cars, material need high strength and toughness, benchmarking injection molded PC parts

● Production Difficulty:

Large size, small quantity, and easy appearance of sand holes on the surface

● Material: PC+ABS

● Size: 1980 * 430 * 380mm

● Delivery time: 25 days

● Quantity: 100 pieces

Production Solution:

(1) Provided by the customer, Make 3D drawing through reverse scanning based on the samples

(2) Confirm the appearance and size through 3D printing sampling. Due to the large size, adopt disassemble printing and then splicing

(3) Based on the requirements of size, quantity, and material properties, Reaction Injection Moulding (RIM) was selected for production, which can achieve high material strength and toughness, realize low-cost mold production, and complete delivery in a relatively short lead time

Urethane casting Car lampshade base

● Requirement: Assemble with lampshade, with even assembly clearance and flame retardant material requirements

● Difficulties: difficult to control dimensional tolerances, difficult to demold internal buckles, small quantity

● Quantity: 60 sets

● Material: Nylon PA Glass-filled

● Delivery time: 20 days

Production Solution:

● The material requires flame retardancy and is used for the base of car lampshades,recommended to use nylon pa glass-filled material.

● Parts are with complex structure and a small quantity. And it's prone to defects during the production process and has a high scrap rate. If the mold is opened according to traditional processes, mold cost will be very expensive. Therefore, suggest to use the urethane casting process for small-scale production

1. Create a prototype by 3d printing, and then polish the surface

2. Use prototypes to make silicone molds

3. Surface polishing and painting

4. Testing

5.13 days to achieve product delivery

3D print Automotive air conditioning ventilation duct

● Requirement: Need to create a fast prototype for size, structure and functional verification

● Difficulties: Small quantity, urgent delivery time, irregular structure, requiring temperature resistance of 100 degrees and flame retardancy

● Quantity: 5 sets

● Material: Nylon PA12

● Delivery time: 5 days

Production Solution:

The customer requested product validation in a short period of time. If open mold, the cost is high, and delivery time is too long, and the irregular structure cannot be processed by CNC. Finally, MJF 3D printing and PA12 were selected

1. First perform data slicing

2. Import data and print it on the computer

3. Cooling and powder cleaning of the machine

4. Surface sandblasting+painting

5.Testing and delivery in time