Name: Precision CNC Aluminum Parts

Material: Aluminum alloy 6061

Process: CNC machining, electric discharge

Surface: Light knife effect

Tolerance:+/-0.005mm

Delivery time: 5 days

CNC aluminum metal parts

Why Choose Aluminum for CNC machining?

Aluminum alloy has low density, light weight, easy processing, and good surface treatment effect,so it's favored by engineers in various industries.

Aluminum alloy models include 5052, 6061, 6063, 6082, 7075, etc. For commonly used material warehouses, there is inventory available, which is convenient for direct use during processing and shortens delivery time

How to choose material for CNC parts?

1). If you want good anodizing effect, you can choose AL6061.

2). If you want high hardness, it is recommended to choose AL7075 and AL2024.,

What surface treatment are available for CNC aluminum parts?

There are many options for surface treatment of aluminum alloy processing products, such as anodizing, powder spraying, painting, electroplating, passivation, polishing, wire drawing, sandblasting, screen printing, laser engraving, electrophoresis, CD pattern, etching, high gloss, etching, dripping glue, etc

What industries are CNC machining aluminum parts suitable for?

CNC aluminum is widely used, covering almost all industries: camera equipment products, radiator products, flashlight products, automotive parts, motorcycle parts, mechanical parts, aviation parts, ship parts, electronic appliances, lighting, furniture, sports equipment, scientific equipment, etc.

Application cases of cnc aluminum machining:

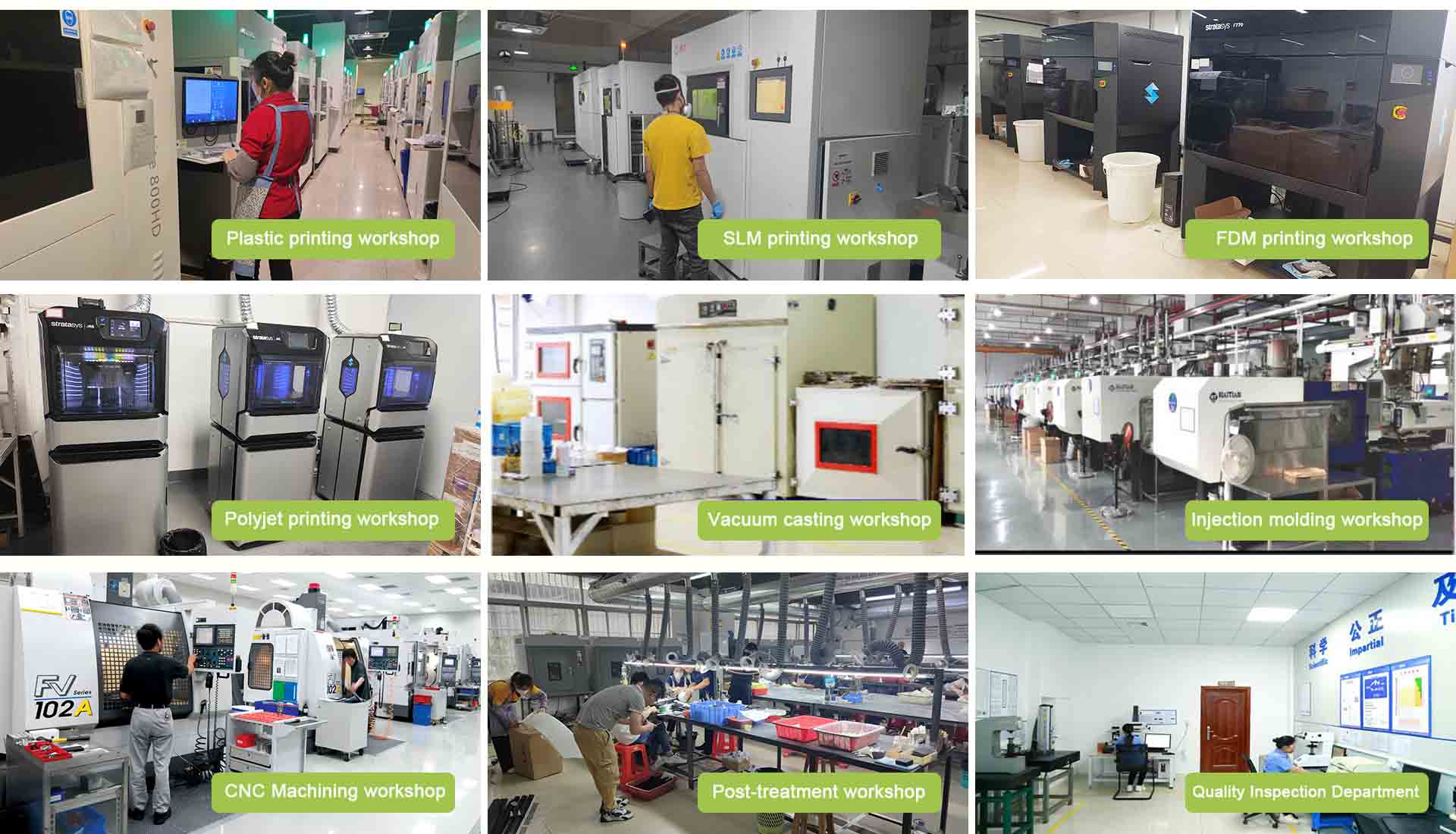

YYI Tech Factory and equipment display

300+sets rapid prototyping equipment, complete materials, complete processes, and comprehensive equipment to meet your various customization needs

About YYI Tech

A professional one-stop rapid prototyping manufacturer

Dongguan Yyi Technology is a professional OEM plastic parts & Metal Fabrication factory located in Dongguan, China and specialize in this field since 2011. Our main business is 3D printing service, vacuum casting,CNC machining, plastic injection molding,and sheet matal Fabrication.Own over 200 professional staff and 2300+sets printing devices ,CNC machining center,drilling and milling machine etc.With these machines and experienced employees, we are able to provide strong guarantee for precision and strength parts. we stive to exceed our customer's expectation in all aspects of product manufacturing process, and recognize our great responsiblities to our customers,employees, suppiers and society. we keep adopting advanced production facilities to improve efficiency and ensure high and stable qualtity, and further reduce the production cost. The objective is to create reliable,viable and affordable prototype,plastic and metal parts and fast sample service for every industry

Why Choose YYI Tech

Whether you need new product development verification or personalized customization, YYI Tech can meet your needs

Integrated solution

Integrated solution

One-stop service

One-stop service

Powerful service capability

Powerful service capability

Fast delivery time

Fast delivery time

High quality & Excellent price

High quality & Excellent price

Data confidentiality

Data confidentiality

FAQ