Name: Precision CNC Copper Parts

Material: Copper

Process: 5-axis CNC machining

Tolerance:+/-0.001mm

Delivery time: 3 days

Custom CNC Copper metal parts

Why Choose Copper for CNC machining?

Copper has excellent properties such as conductivity, thermal conductivity, ductility, corrosion resistance, and wear resistance, which is widely used in fields such as power, electronics, energy and petrochemical, machinery and metallurgy, transportation, and light industry

What material can you choose for CNC copper parts?

| Material | Metal grade | Characteristic | Application | |

| Pure copper | T1、T2、T3、TU1、TU2 | Density is 8.96, melting point is 1083 ℃, good conductivity thermal conductivity, and excellent plasticity | Electrical switches, electronic components, etc | |

| Brass | H59、H62、H65、H68、HPb59-1 | Good cold working performance, high strength, and corrosion resistance to seawater | Corrosion resistant parts for ships, watch parts, valves, and pipeline components | |

| Bronze | B19、B25、BA13-3 | Good friction reduction performance, mechanical performance | suitable for manufacturing high load and harsh parts such as bearings, worm gears, gears, shaft sleeves, etc. | |

| Copper-nickel | BZnl8-18,BZnl8-26,BZnl5-20,BZnl8-10 | Good mechanical performance, corrosion resistance, beautiful color, and good thermoelectric performance | precision instruments, medical devices, chemical machinery, ship parts, clock parts, etc |

What surface treatment are available for CNC copper parts?

Due to copper being a very active metal, it is easy to oxidize in humid or special environments, resulting in surface spots and even the appearance of copper green

1). Passivation

Passivation has the function of preventing oxidation and corrosion, so passivation treatment for copper parts can effectively protect the surface effect of copper products.

2). Electroplating

Copper parts have excellent conductivity and are the most effective among all hardware materials. Electroplating can also enhance copper's corrosion resistance, increase hardness, prevent wear, improve conductivity, smoothness, heat resistance, and surface aesthetics.

Application of CNC Copper:

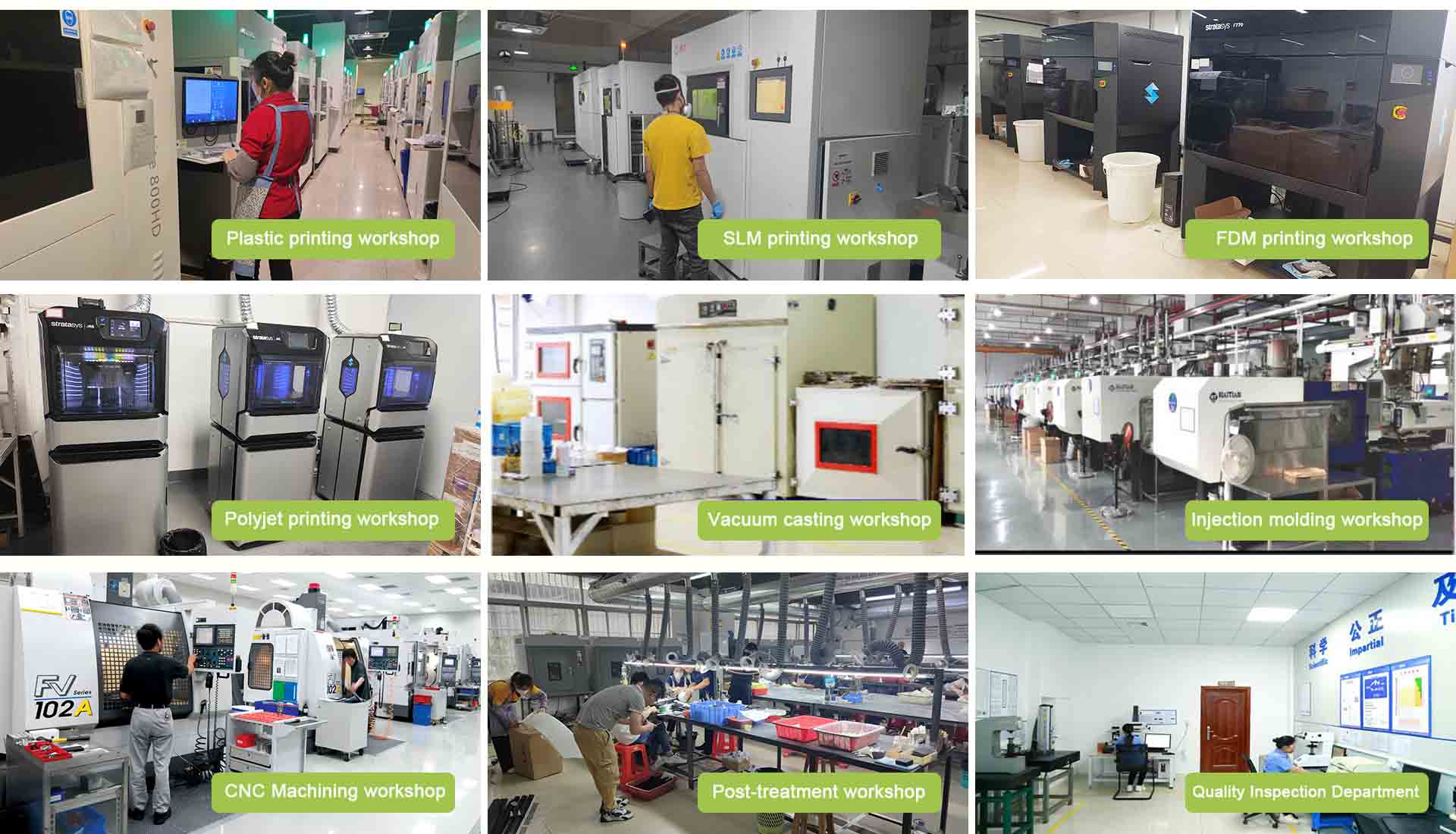

YYI Tech Factory and equipment display

300+sets rapid prototyping equipment, complete materials, complete processes, and comprehensive equipment to meet your various customization needs

About YYI Tech

A professional one-stop rapid prototyping manufacturer

Dongguan Yyi Technology is a professional OEM plastic parts & Metal Fabrication factory located in Dongguan, China and specialize in this field since 2011. Our main business is 3D printing service, vacuum casting,CNC machining, plastic injection molding,and sheet matal Fabrication.Own over 200 professional staff and 2300+sets printing devices ,CNC machining center,drilling and milling machine etc.With these machines and experienced employees, we are able to provide strong guarantee for precision and strength parts. we stive to exceed our customer's expectation in all aspects of product manufacturing process, and recognize our great responsiblities to our customers,employees, suppiers and society. we keep adopting advanced production facilities to improve efficiency and ensure high and stable qualtity, and further reduce the production cost. The objective is to create reliable,viable and affordable prototype,plastic and metal parts and fast sample service for every industry

Why Choose YYI Tech

Whether you need new product development verification or personalized customization, YYI Tech can meet your needs

Integrated solution

Integrated solution

One-stop service

One-stop service

Powerful service capability

Powerful service capability

Fast delivery time

Fast delivery time

High quality & Excellent price

High quality & Excellent price

Data confidentiality

Data confidentiality

FAQ