Consumer electronics

Consumer electronics - On demand rapid manufacturing

From air conditioners to electric water heaters to toys to various electronic products, people's constantly expanding demands and increasing emphasis on fashionable appearance have led to the continuous improvement of products with various functions, forcing manufacturers to update and replace their products more and more quickly. If design defects are not discovered in a timely manner during the design stage, it will bring huge losses to manufacturers. The application of rapid prototyping technology is widespread, and it can be believed that with the continuous maturity and improvement of rapid prototyping manufacturing technology, it will be promoted and applied in more and more fields.

YYI TECH can flexibly and comprehensively utilize various RP technologies to carry out design verification and simulation sample trial production for the development of new products (including product updates), as well as small-scale production, helping manufacturers to meet customer personalized customization while reducing development cycles, lowering development costs, and improving product performance.

What needs has YYI TECH solved in the Consumer electronics manufacturing field?

● Comprehensive solution

A large design team, mature technical team, and attentive service team have the ability to provide customers with comprehensive solutions from requirements to products.

● Personalized customization

Cross border technology integration, diversified material selection, and complete printing processes enable us to provide personalized customization for customers, whether it is personalized household appliances, electronic products, decorations, glasses, shoes, cultural products, or office gifts.

● Complex process

The combination of advanced rapid prototyping technology and traditional techniques provides a guarantee for the production of complex consumer goods, bringing surprises and shocks to customers.

● Strong design ability

We have a large design team that can meet the various consumer product design needs of our clients and provide timely solutions.

● Diversification of materials

Hundreds of materials to choose from give consumer goods new life and vitality, bringing customer satisfaction

● Strict quality assurance

From interpreting product requirements to every stage of product production, there is strict quality control to ensure that the products accepted by customers are qualified.

Personalized customization & design freedom

One of the main advantages of rapid prototyping in consumer electronics is the customization of products based on personal preferences and characteristics, from personalized small appliances to headphones to shoes. For traditional manufacturing, producing customized products for specific applications requires a significant amount of manpower and design/production costs. However, various advanced processes through rapid prototyping can design and produce customized products faster and more economically, as it is not limited by expensive processing costs.

Moreover, the production of auxiliary equipment and injection molds can also benefit from rapid prototyping. For example, 3D printing accompanies waterways to help companies shorten molding cycles and increase production capacity. Therefore, rapid prototyping can change the production mode of consumer products and has relative advantages in small batch customized production.

The flexible application of various advanced rapid prototyping has greater design freedom, providing product development engineers with enormous imagination and design space. Although powerful 3D design software can turn ideas into design documents no matter how complex the product is designed, complex mechanisms can pose significant challenges to traditional production methods, and costs can also deter you.

Rapid prototyping can not only achieve "free design", but also "unrestricted manufacturing".

Classic case we have done

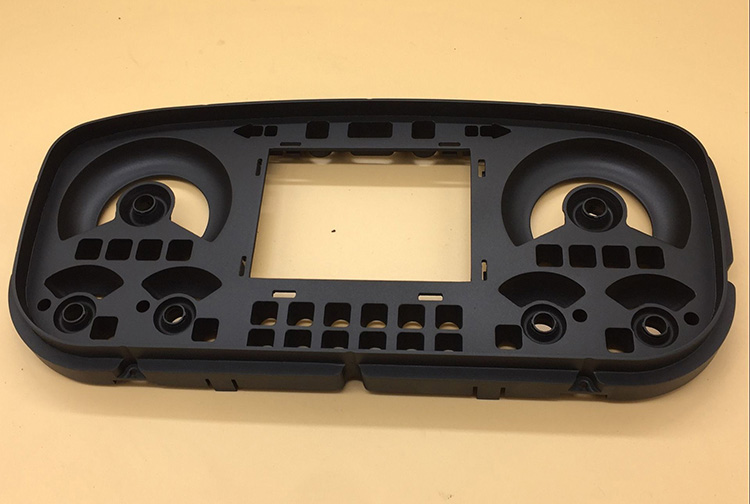

CNC machining ABS Plastic casing for electrical appliances

● Customer requirements:

Prototype verification parts, size and assembly effect need to be verified

● Production difficulties:

Product structure is complex, the processing difficulty is high and time-consuming, and the product is too large and prone to deformation

● Quantity: 2pcs

● Material: ABS

● Process: CNC machining process

● Delivery time: 7days

Our Production solution:

(1) Quantity 2pcs, due to the small quantity requirement, and tight delivery time, consider rapid prototyping technology

(2) The product structure is complex and the size is relatively large, with high material requirements

(3) Based on the above requirements, suggest CNC machining processes with ABS material (no need open mold, and no MOQ), delivery time only need 7days

3D printing resin 3C electronic product plastic casing

● Customer requirements:

Prototype verification, verifying appearance and structure

● Production difficulties:

High surface requirements and high assembly accuracy

● Quantity: 5pcs

● Material: Resin

● Process: 3D printing+surface treatment

● Size: 105 * 48 * 48mm

● Delivery time: 7days

Our Production solution:

(1) Quantity 5pcs, and 5colors,quantity is small, color is different each one, and tight delivery time, consider rapid prototyping technology with surface polishing and painting

(2) The client's budget is limited, so we recommend SLA 3D printing with resin, This process and material cost are relatively low, and the appearance can be made very beautiful

Injection Molding charging power supply casing

● Customer requirements:

Need 5000 sets of charging cases, with high gloss effect on the surface and no defects on the surface

● Production Plans:

According to customer requirements, the steel film injection molding production process is adopted, and the surface is treated with UV

● Quantity: 5000sets

● Material: PC+ABS

● Process: Injection molding process

● Delivery time: 40days