Craftwork & Construction

Craftwork & Construction - On demand rapid manufacturing

In the field of culture and art, YYI is able to integrate various rapid prototyping technologies, allowing artists to freely unleash their creativity and create more intricate and complex works.

In the construction industry, rapid prototyping technology is used for the rapid production of building models. YYI TECH integrates one-stop rapid prototyping technology to assist architects in creating prototypes of building models, in order to better showcase design concepts and communicate with clients. In addition, we can manufacture some complex building components to improve construction efficiency.

What problems has YYI TECH solved in the field of Craftwork & Construction manufacturing?

● Enhance original design

Quickly obtain design elements through 3D digital means, integrate them into original product designs, save 60% of development time, achieve maximum freedom of creative ideas for designers, and unleash more inspiration for designers.

● Improve the speed of handicrafts and reduce costs

3D digitalization can enlarge and shrink products, and then produce them through rapid prototyping technology to achieve rapid replication of different sizes

● Improve the quality of handicrafts

Through computer CG technology, product design can be completed more efficiently, with a sample pass rate of over 90% in Japan and Disney products

● Gift customization

Avoid uniformity, demonstrate care and dedication, and make gifts unique and worth their money.

● Cultural relic protection and restoration

Digitize various cultural relics, artworks, historical buildings, etc. in three dimensions to record their appearance, display them online, or serve as a basis for physical replication. Meanwhile, rapid prototyping technology can help achieve precise restoration and repair of cultural relics.

Application of rapid prototyping in Craftwork & Construction industry

■ Digital design and scaling of sculptures

■ Cultural relic restoration, virtual display

■ Development of cultural relics derivatives

■ Toy model

■ Ornament, decoration

■ Reproduction of artworks

■ Sand table and model

■ Bridge model

■ Historical architecture

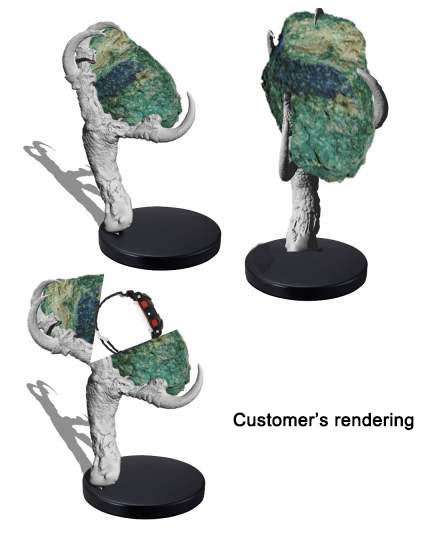

Classic case we have done

Vacuum casting Resin watch box

● Customer requirements:

Make a watch box based on the rendering, which can be opened and closed, fixed on claws, or removed from claws

● Production difficulties:

No 3D drawings, no sample, only an unclear rendering, no specific standard for paint color, the box needs to be opened and closed, and the sponge inside needs to be able to securely hold the watch, but no watch sample,box needs to be fixed on the claws and removed from claws

● Quantity: 100pcs

● Material: Resin

● Process: Vacuum casting+SLA 3d printing+painting+assembly

● Delivery time: 30days

Our Production solution:

(1) Create 3D drawing

No 3D drawings, no samples, only a conceptual rendering, which is very tricky. Our professional engineering designers considered that the box needs to be firmly fixed on the claws, and designed invisible buckles on the claws. The box needs to be opened and closed, and also specially designed the position and buckle of the hinges. The overall shape is based on the required functions, dimensions, and appearance of the product, and 3D drawings are made for customer confirmation

(2) Make a prototype

After confirming the drawings, print a sample using SLA 3d printingto confirm the appearance and dimensions of the product.

(3) Confirm the opening and closing hinges and locks

Considering the overall color coordination of the product, the color of the hinges is also a retro color that we have specifically searched for in the market and confirmed with customers before adopting it. Considering customs transportation issues, the product opening and closing lock did not use magnets, but instead used buckles to lock it

(4) Creating the built-in sponge

Due to the need for a built-in sponge to secure the watch, but no sample or drawing of the watch, so our engineering designer created a simple 3D drawing that fits customer's watch size and produced a watch sample through SLA 3D printing.Made a mold for the sponge based on the internal structure of the box and the watch sample. After completion, it is installed and tested and once confirmed by the customer, it is adopted

(5)Confirm the surface painting color

Based on the color concept provided by the customer, spray paint repeatedly for customer confirmation until the desired color effect is achieved

(6) Small-scale production

After sample confirmation, based on the structure and quantity of the product, adopted vacuum casting process, and gypsum molds were opened to achieve the best quality, most affordable price, and shortest delivery time

SLA Resin 3D printing helmet mask

● Customer requirements:

The surface needs to be highly consistent with the rendering and needs to be assembled before shipment

● Production difficulties:

The color needs to be almost identical to the rendering, the painting color is difficult to adjust, too many small accessories, the assembly is difficult, and the shipment is prone to breakage

● Quantity: 1pc

● Material: Resin

● Process: SLA 3d printing+painting+assembly

● Delivery time: 10days

Our Production solution:

(1) Adjust the assembly gap of the drawing

After checking the drawings, our engineer found that the customer did not leave assembly gaps, and a 0.5mm assembly gap was reserved for unilateral modification of each component,which took 1 day.

(2) Confirm the production process

The product quantity is 1pc, so adopted SLA resin 3D printing technology to print each accessory,which took 1day.

(3) Confirm the surface treatment process

Disassemble and print parts of different colors, polish all the surface before painting,Black stripes on the mouth and forehead, using water transfer printing to create a carbon fiber texture. After all surface treatments are completed, assemble and paste all accessories, which will take 5 days

(4) Package

Due to the fact that the product is a plastic helmet with many small parts, it is easy to cause breakage during transportation. Considering this situation, we made a wooden box and filled it with pearl cotton to prevent transportation compression and collision injuries