Electronic&Electrical parts Injection Molding

How to solve the problem of missing material in injection molding plastic shells?

Lack of material, also known as insufficient filling, is one of the common problems in the injection molding process. The injection molded parts are not full, and there are bubbles, gaps, shrinkage holes, etc. that do not match the standard sample, which is called lack of glue. So how does a professional injection mold factory solve the problem of plastic shell missing glue?

The following are the reasons and improvement measures for the lack of plastic in professional injection mold factories:

① In terms of molds: A. The design of the pouring system is unreasonable. The pouring system is a channel for the molten metal to enter the mold cavity, which has a great impact on the quality of plastic parts molding. The pouring gates are not parallel and are not located in the thick wall area; B、 Poor exhaust structure of the mold; C、 Impurities or cold materials in the melt block the flow channel; D、 The mold temperature did not meet the requirements. Improvement measures: Improve the pouring system, increase mold exhaust, remove impurities from the rubber material, and increase mold temperature.

② In terms of raw materials: A. The moisture content of the raw materials is too high; B、 Excessive volatile compounds in raw materials; C、 Excessive impurities or recycled materials in raw materials. Improvement measures: Barbecue the ingredients and increase the amount of raw materials.

③ In terms of injection molding machines: A. Insufficient injection volume: such as using a 150T machine to produce 180T products. B、 The nozzle is blocked by foreign objects and the nozzle hole is too small; C、 Shortage of raw material supply: such as blockage of the material cylinder, water outlet material affecting feeding; D、 Check valve malfunction; E、 The injection stroke is insufficient. Improvement measures: Increase injection volume and increase injection duration.

④ In terms of molding operation: A. The mold temperature is too low; B、 The injection pressure is too low; C、 The holding time is too short; D、 The injection speed is too slow; E、 The melt temperature is too low. Improvement measures: Increase mold temperature, increase injection pressure, holding time, and improve injection speed.

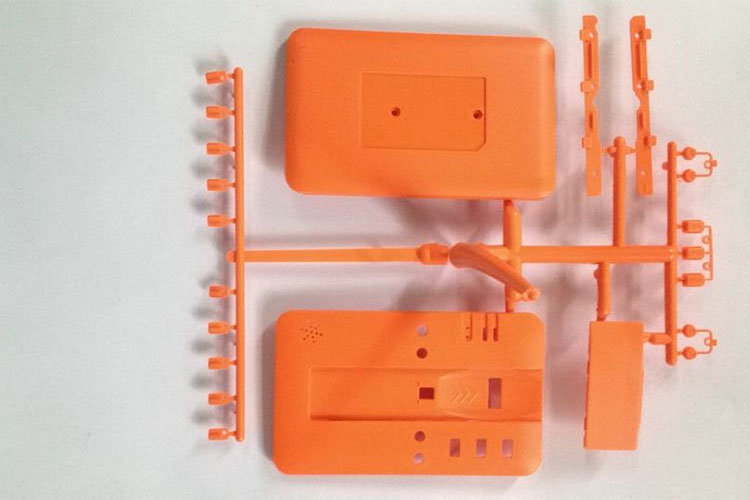

Cases we have done

Doorbell shell-low volume plastic injection molding

Intelligent switch panel-low volume plastic injection molding

SmartWatch shell-low volume plastic injection molding

Mobile power supply housing-low volume plastic injection molding

Portable power source-low volume plastic injection molding

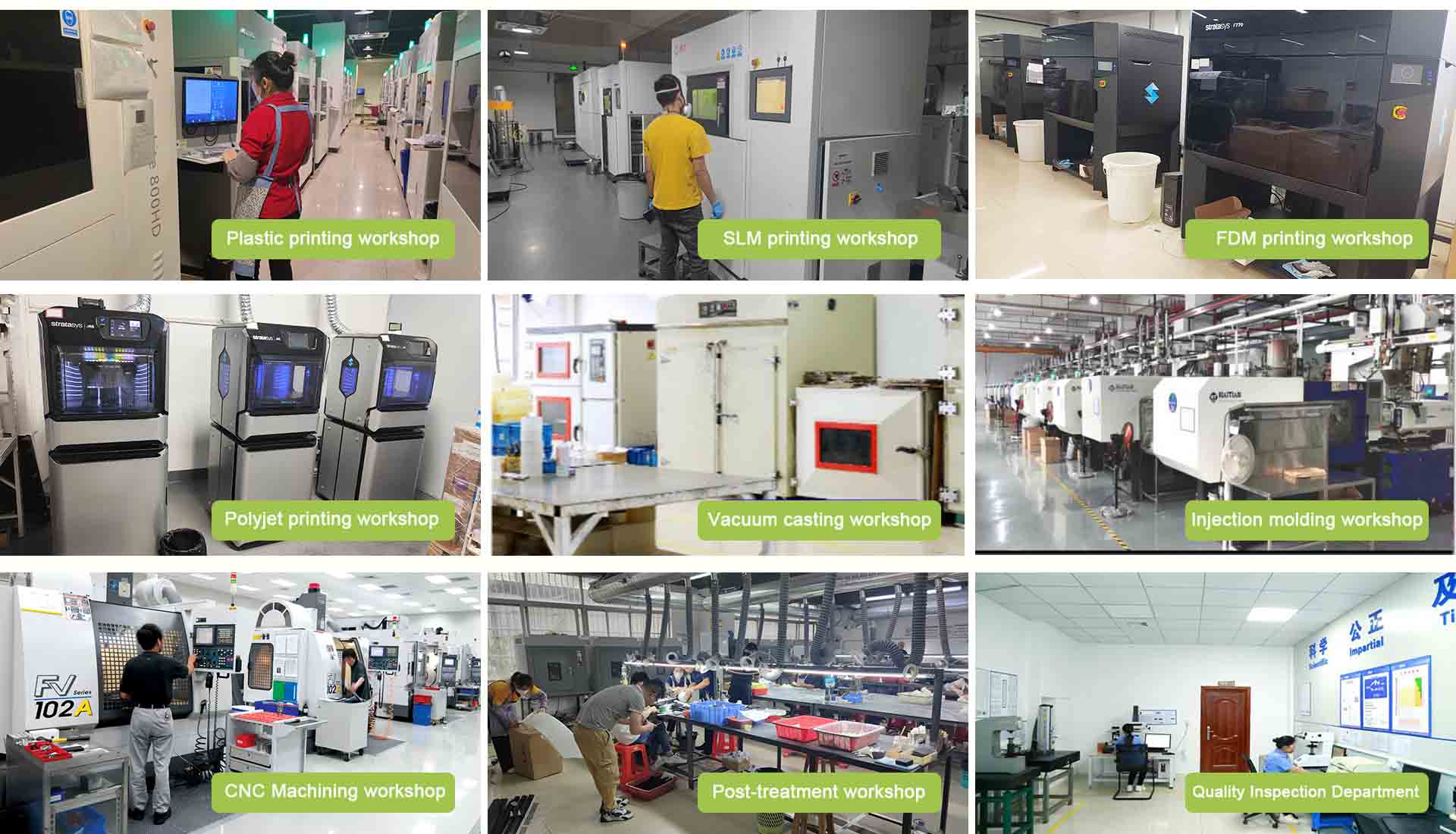

YYI Tech Factory and equipment display

300+sets rapid prototyping equipment, complete materials, complete processes, and comprehensive equipment to meet your various customization needs

About YYI Tech

A professional one-stop rapid prototyping manufacturer

Dongguan Yyi Technology is a professional OEM plastic parts & Metal Fabrication factory located in Dongguan, China and specialize in this field since 2011. Our main business is 3D printing service, vacuum casting,CNC machining, plastic injection molding,and sheet matal Fabrication.Own over 200 professional staff and 2300+sets printing devices ,CNC machining center,drilling and milling machine etc.With these machines and experienced employees, we are able to provide strong guarantee for precision and strength parts. we stive to exceed our customer's expectation in all aspects of product manufacturing process, and recognize our great responsiblities to our customers,employees, suppiers and society. we keep adopting advanced production facilities to improve efficiency and ensure high and stable qualtity, and further reduce the production cost. The objective is to create reliable,viable and affordable prototype,plastic and metal parts and fast sample service for every industry

Why Choose YYI Tech

Whether you need new product development verification or personalized customization, YYI Tech can meet your needs

Integrated solution

Integrated solution

One-stop service

One-stop service

Powerful service capability

Powerful service capability

Fast delivery time

Fast delivery time

High quality & Excellent price

High quality & Excellent price

Data confidentiality

Data confidentiality

FAQ