Customization and small batch production

FDM 3D printing service starting at only $14 and MOQ 1pc

How does Industrial grade FDM Plastic 3D printing work?

The principle of Industrial grade FDM rapid prototyping:

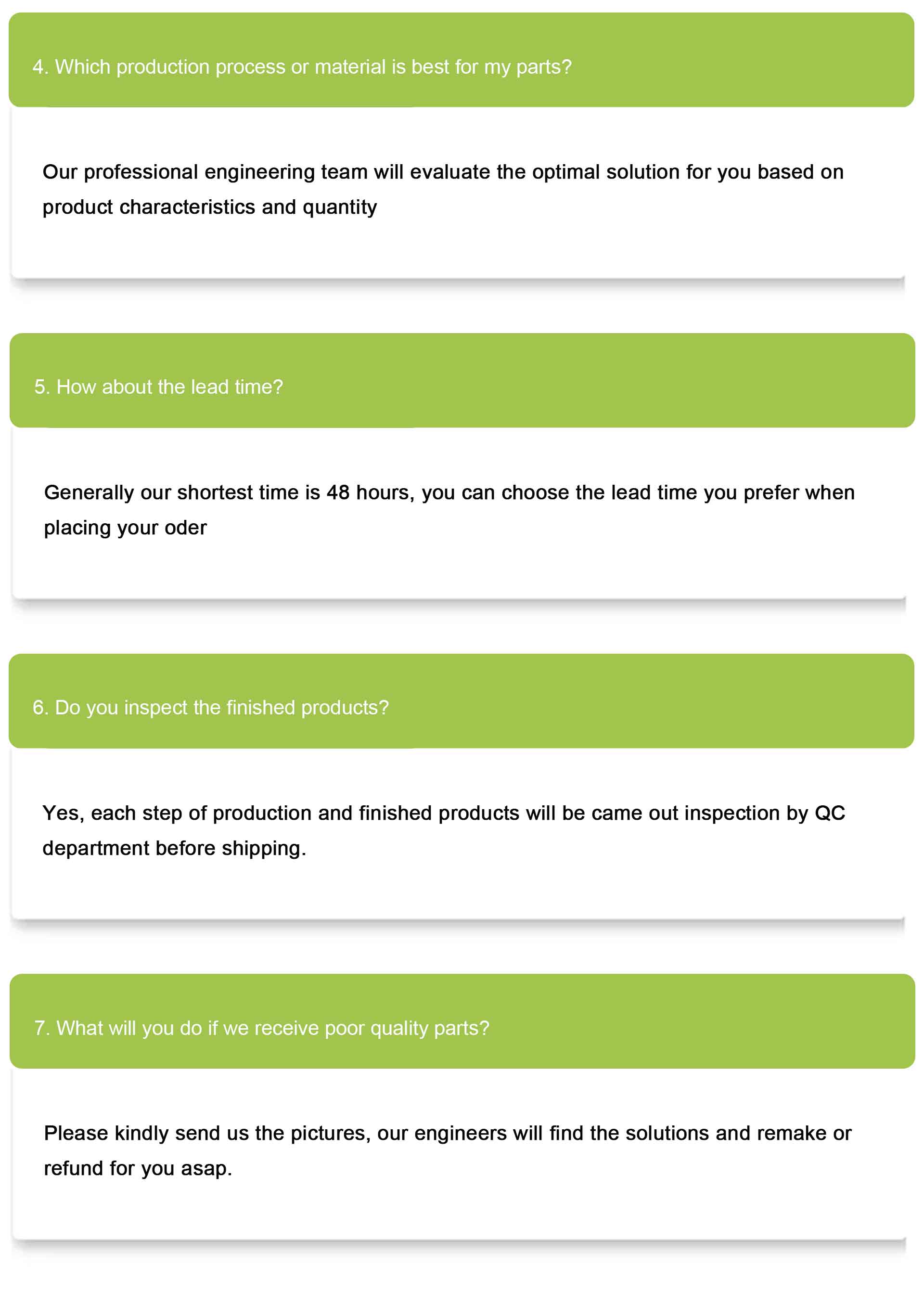

The filamentous thermoplastic material is heated and melted through a nozzle, with a micro nozzle (usually 0.2-0.6mm in diameter) at the bottom of the nozzle. Under computer control, the nozzle moves to a designated position based on the data of the 3D model, extruding the molten liquid material and finally solidifying it. After the material is sprayed out, it is deposited on the previous layer of solidified material, and the final product is formed by stacking the material layer by layer.

Industrial grade FDM 3D printers are mostly used in large-scale industrial production, in various fields such as aerospace, automotive, medical, and electronic products

FDM Working principle

Advantages of Industrial grade FDM 3D printing rapid prototyping:

(1)Due to the simple construction principle and operation of the hot melt extrusion head system, low maintenance cost, and safe system operation;

(2)The molding speed is slow, and products produced using the melt deposition method do not require the scraper processing process in SLA;

(3)Prototypes of parts formed with wax can be directly used for investment casting;

(4)Can shape parts of any complexity, commonly used for forming parts with very complex cavities, holes, etc;

(5)The raw materials have no chemical changes during the forming process, and the warping deformation of the parts is small;

(6)High utilization rate of raw materials and long material life

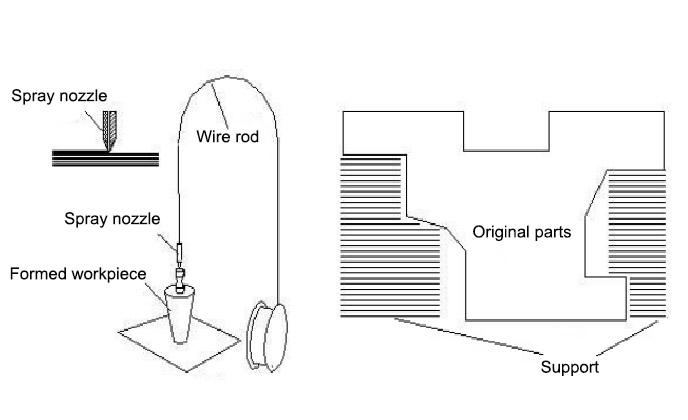

What materials can you choose for Industrial grade FDM plastic 3D printing?

The materials of FDM are generally thermoplastic materials, such as wax, ABS, nylon, etc. Feed in filamentous form. The material is heated and melted inside the nozzle. The nozzle moves along the cross-sectional profile and filling trajectory of the part, while extruding the melted material, which quickly solidifies and condenses with the surrounding material

|

Characteristic |

Material |

Color |

Tolerance |

Max Build Size(mm) |

|

High strength,toughness, lightweight and elastic |

ABS |

Black |

±0.2mm |

1000*610*610 |

| Excellent UV resistance, mechanical properties, and aesthetics |

ASA |

Off-white |

±0.2mm |

1000*610*610 |

|

High toughness and high temperature resistance |

PC |

White |

±0.2mm |

406*355*406 |

|

Chemical resistance and high temperature |

PEEK |

yellowish-brown |

±0.2mm |

914*610*914 |

Case studies of Industrial grade FDM Plastic 3D printing:

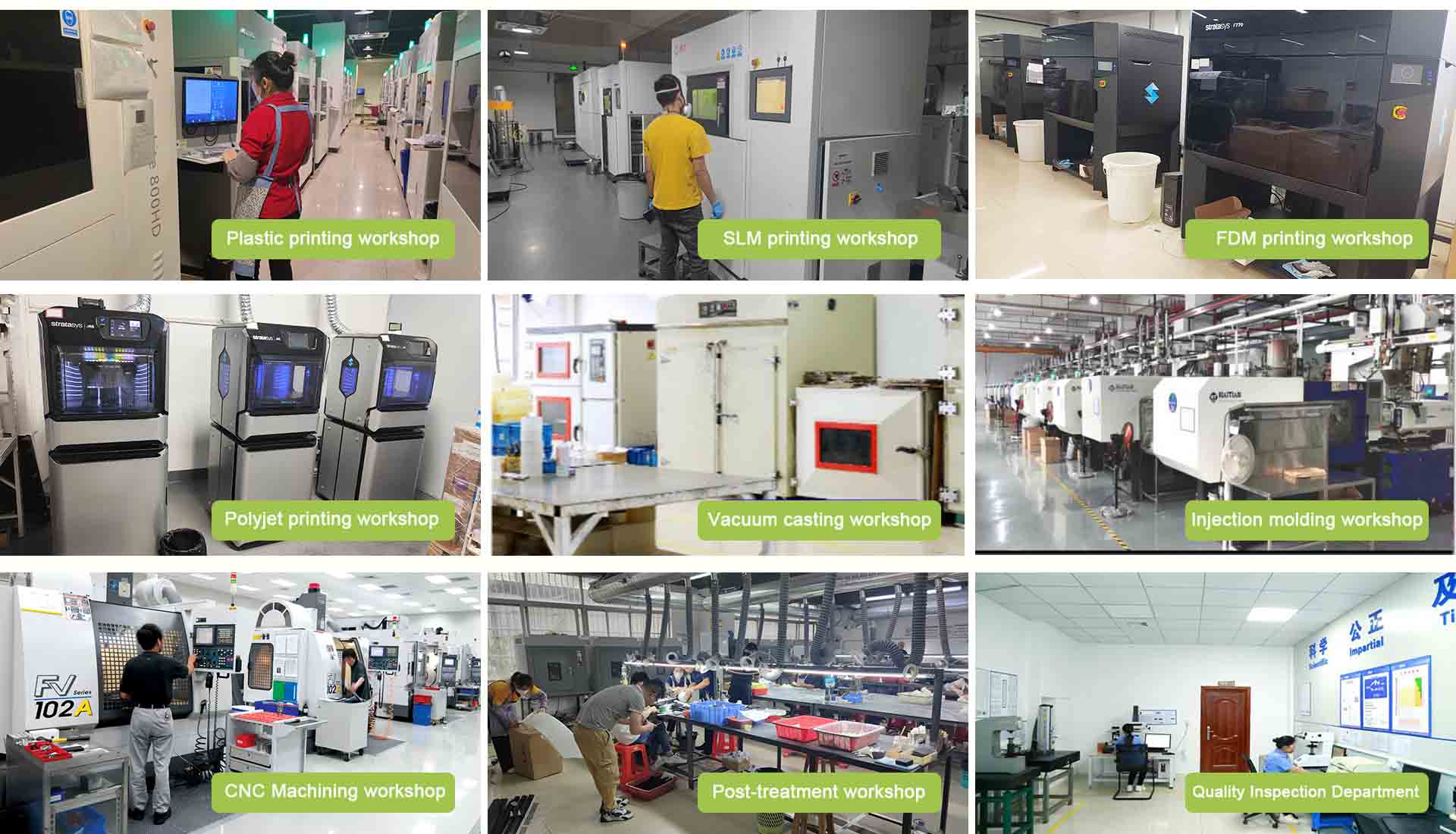

YYI Tech Factory and equipment display

300+sets rapid prototyping equipment, complete materials, complete processes, and comprehensive equipment to meet your various customization needs

About YYI Tech

A professional one-stop rapid prototyping manufacturer

Dongguan Yyi Technology is a professional OEM plastic parts & Metal Fabrication factory located in Dongguan, China and specialize in this field since 2011. Our main business is 3D printing service, vacuum casting,CNC machining, plastic injection molding,and sheet matal Fabrication.Own over 200 professional staff and 2300+sets printing devices ,CNC machining center,drilling and milling machine etc.With these machines and experienced employees, we are able to provide strong guarantee for precision and strength parts. we stive to exceed our customer's expectation in all aspects of product manufacturing process, and recognize our great responsiblities to our customers,employees, suppiers and society. we keep adopting advanced production facilities to improve efficiency and ensure high and stable qualtity, and further reduce the production cost. The objective is to create reliable,viable and affordable prototype,plastic and metal parts and fast sample service for every industry

Why Choose YYI Tech

Whether you need new product development verification or personalized customization, YYI Tech can meet your needs

Integrated solution

Integrated solution

One-stop service

One-stop service

Powerful service capability

Powerful service capability

Fast delivery time

Fast delivery time

High quality & Excellent price

High quality & Excellent price

Data confidentiality

Data confidentiality

FAQ