In today’s fast-evolving world of product design and manufacturing, Fused Deposition Modeling (FDM) has emerged as a versatile and cost-effective 3D printing technology. By enabling rapid prototyping and functional part production, FDM is bridging the gap between conceptualization and realization.

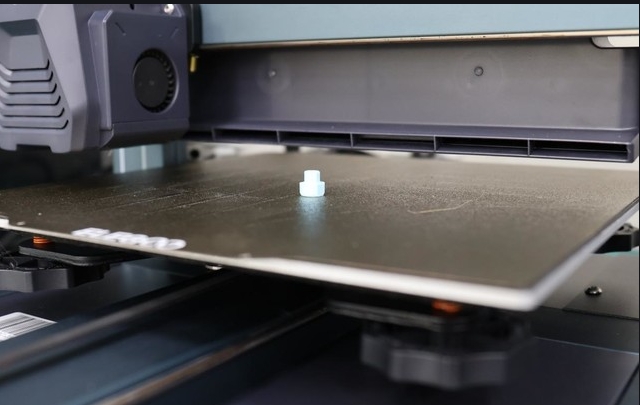

FDM, also known as Fused Deposition Modeling, is a layer-by-layer additive manufacturing technique. It utilizes thermoplastic filaments, which are heated to their melting point and precisely extruded to build parts from the bottom up. This process is guided by a 3D model, ensuring accuracy and repeatability.

Cost-Efficiency

Unlike other 3D printing technologies, FDM is highly affordable, making it an excellent choice for startups, educational institutions, and small businesses.

Material Diversity

FDM supports a wide range of materials, including PLA, ABS, PETG, and engineering-grade filaments like Nylon and Polycarbonate. This versatility allows it to cater to diverse industry needs.

Ease of Use

FDM printers are user-friendly, with minimal setup and maintenance requirements. This makes them a popular option for beginners and professionals alike.

Rapid Prototyping

FDM is widely used in the creation of prototypes for testing designs, functionality, and fit. Its ability to quickly turn ideas into tangible models accelerates the design iteration process.

Customized Manufacturing

Whether it's small-batch production or custom parts for specific applications, FDM excels in delivering tailored solutions. For example:

Educational Tools

Many schools and universities use FDM printers to teach students about engineering, design, and manufacturing principles.

DIY and Maker Communities

The affordability and flexibility of FDM have made it a favorite in the maker movement, where creators bring their innovative ideas to life.

While FDM offers a cost-effective and versatile solution, it may lack the fine detail and surface finish provided by SLA (Stereolithography) or the strength of parts produced by SLS (Selective Laser Sintering). However, FDM’s lower barrier to entry and broad material compatibility make it a leader for functional prototypes and everyday 3D printing needs.

At YYI Technology, we specialize in FDM-based 3D printing services that deliver high-quality, precise, and durable results. Whether you need rapid prototyping, small-batch production, or a custom project, we’re here to turn your ideas into reality.

Conclusion

FDM technology is transforming the way we approach design and manufacturing. Its accessibility, affordability, and versatility have made it a cornerstone of innovation for industries and individuals alike. Explore how FDM 3D printing can empower your projects—contact us today to learn more!