Mechanical parts Mold Injection

What is the injection molding process?

Injection molding is the process of using the thermal and physical properties of plastic to add materials from a hopper to a barrel. The outside of the barrel is heated by a heating coil, causing the material to melt. Inside the barrel, there is a screw that is driven to rotate by an external power motor.

The material used in injection molding is transported forward and compacted along the screw groove under the action of the screw. The material is gradually melted and homogenized under the dual effects of external heating and shearing. When the screw rotates, the material is pushed to the head by the shearing force, and at the same time, the material retreats under the reaction force, forming a storage space and completing the plasticization process.

Then, under the action of the piston thrust of the injection cylinder, the molten material in the storage chamber of the injection molding is injected into the mold cavity through the nozzle at high speed and high pressure. After the molten material in the mold cavity is pressurized, cold solidified, and solidified, the mold is opened under the action of the mold closing mechanism, and the molded product is ejected from the mold through the ejection device to complete the injection molding process

Is the delivery time of simple injection molds long??

The method of making simple injection molds is not much different from other molds, and there are still so many production processes: drawing review, material preparation, processing, mold frame processing, mold core processing, electrode processing, mold part processing, inspection, assembly, flying mold, trial mold, and production. No process can be omitted. Because the ultimate goal is to achieve the desired effect for the customer, we cannot just brush it off and make rough workmanship just because the mold is simple.

So it's not that the delivery time of simple injection molds will be shortened, because whether it's a simple or complex process, it's the same. The simpler the mold, the more precise and refined it needs to be. The product made in this way appears less simple, but rather simple and sophisticated. The simpler the mold, the better it should be, which can reflect the technology and strength of mold making.

What affects the injection molding price of injection molded parts?

Many customers have questions about the injection molding price of injection molded parts. Why do different manufacturers have different prices for the same product? What exactly affects the price?

1. Material cost

The price of products will naturally vary greatly depending on the different materials used. For example, plastics include PE, PVC, ABS, PPO, PPS, PC, PP, and other materials. Based on the requirements of the product, the suitable material for the product is selected, and the price of the product in terms of materials is calculated based on the quality and materials of the product. This can basically be clearly calculated.

2. Water and electricity fees

To produce products, electricity, water, or oil must be used, so the cost of water and electricity naturally varies according to different regions. However, this aspect is relatively fixed and will not have significant changes because water and electricity are generally fixed and can be calculated.

4. Worker wages

The wages of workers also vary greatly depending on different regions, and it is not possible to calculate them specifically. However, the differences will not be too significant because products are processed by machines after all.

5. Production capacity

The production capacity directly affects the price of the product, as it can produce 100 pieces per hour and only 50 pieces per hour. The price of producing 100 pieces will definitely be lower, depending on the manufacturer's equipment, such as injection molding machines and molds, which are key to improving production capacity.

6. The price difference between packaging cost, transportation cost, mold cost, machine wear cost, and profit is not significant, so it has little impact on the injection molding price

Mechanical parts Mold Injection case

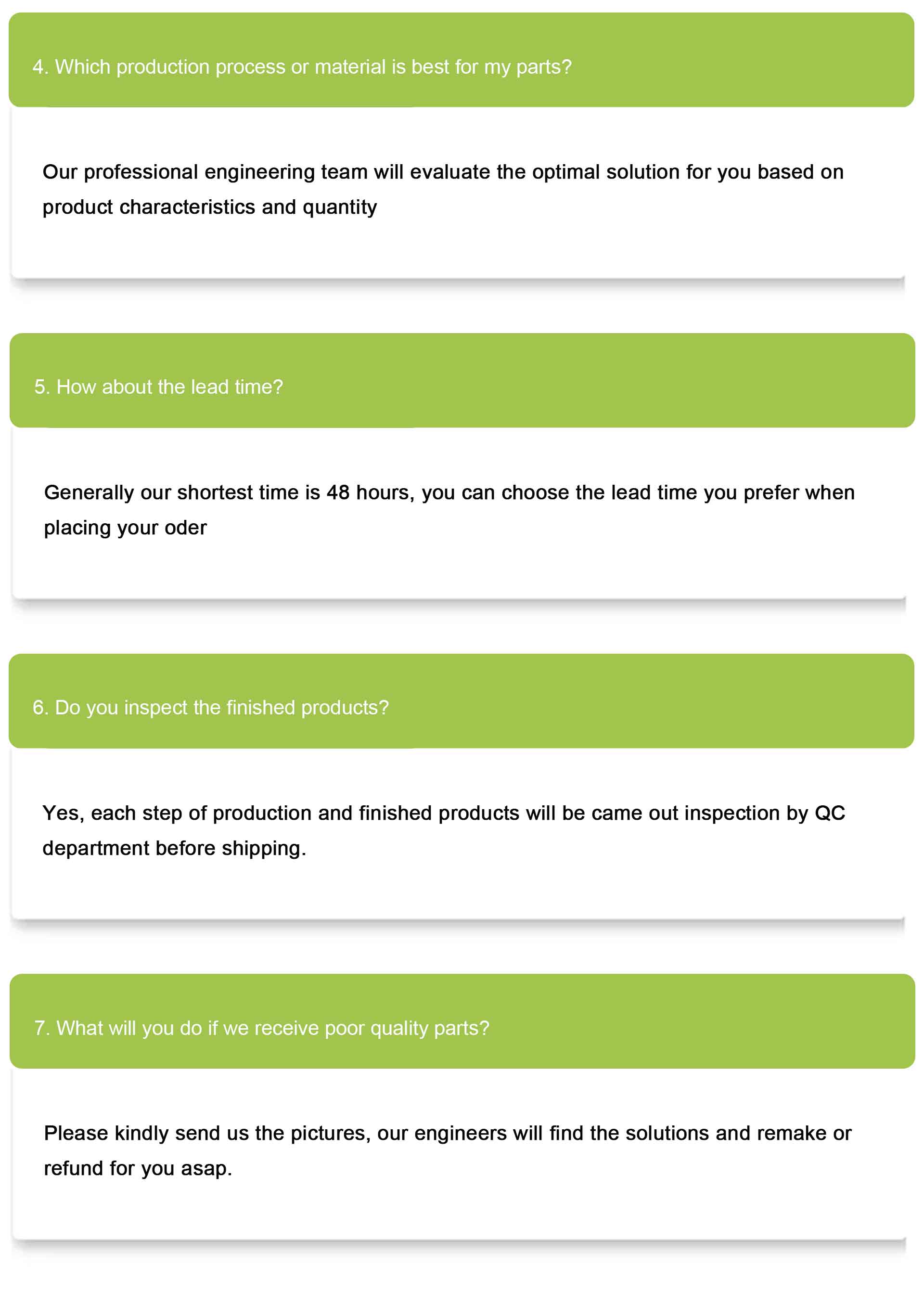

Protective sleeve injection mold

Industrial remote control housing Injection molded parts

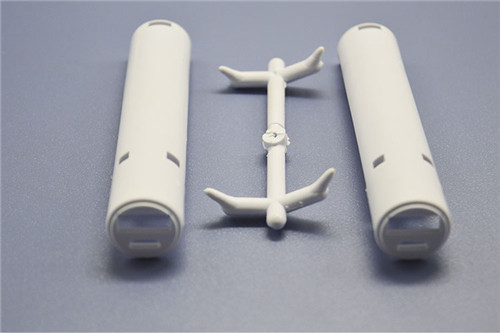

Tightening rubber plugs for petroleum machinery

Product material: High temperature resistant TPU

Mold hole count: 1 out 1

Mold lifespan: 300000 molds

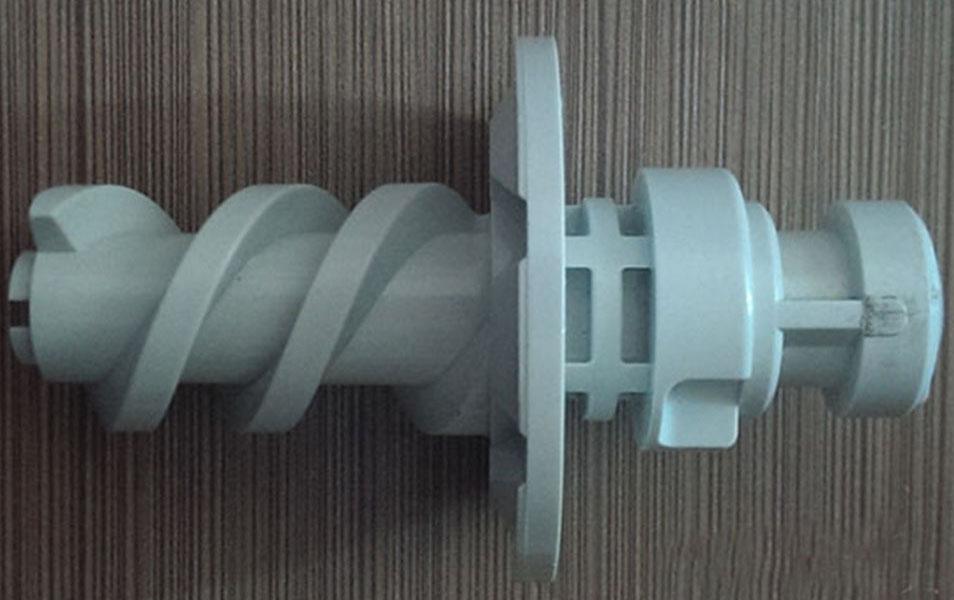

Spiral threaded plastic parts with slope

Product material: PC

Number of mold holes: 1

Mold lifespan: 80w;

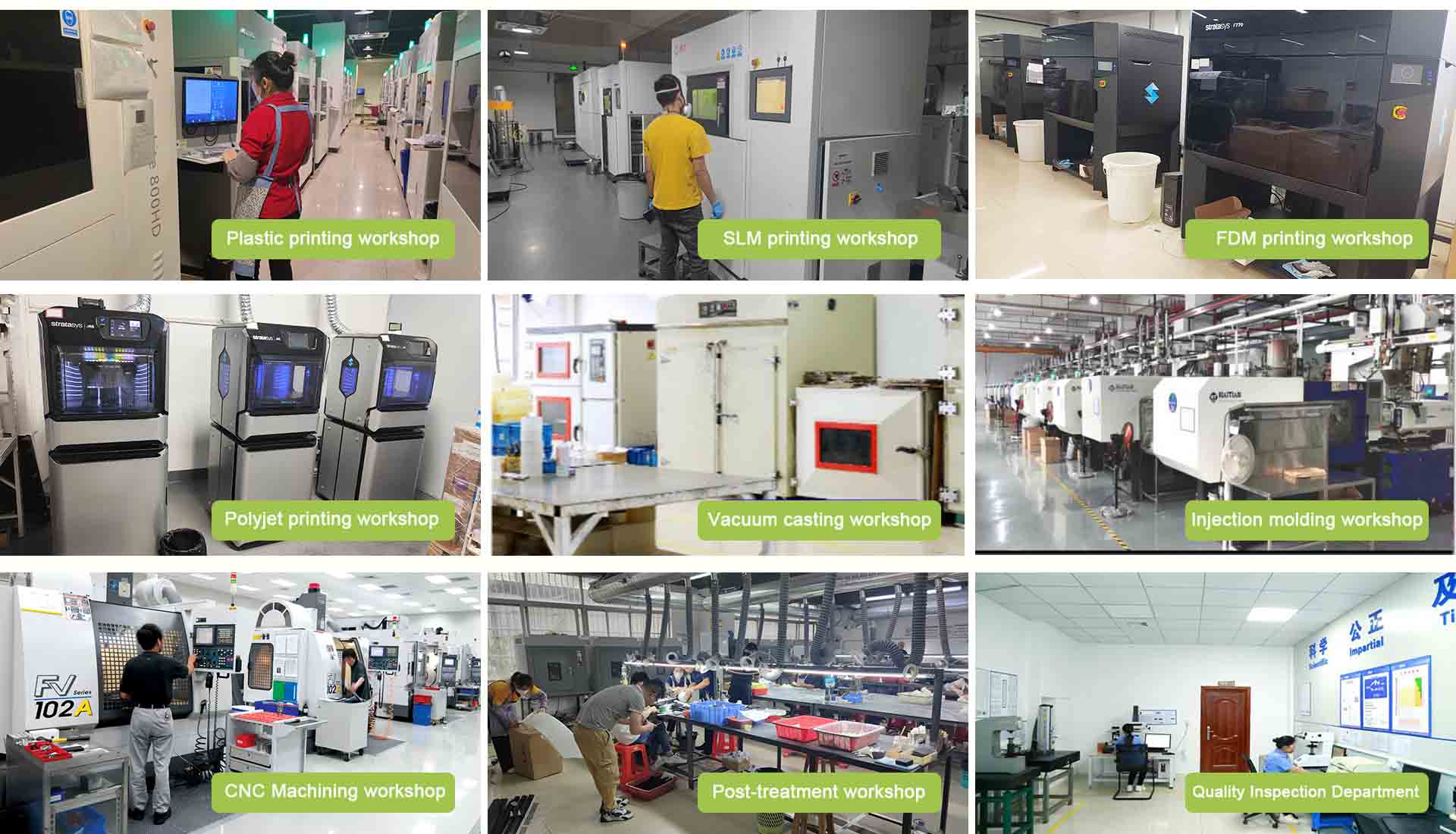

YYI Tech Factory and equipment display

300+sets rapid prototyping equipment, complete materials, complete processes, and comprehensive equipment to meet your various customization needs

About YYI Tech

A professional one-stop rapid prototyping manufacturer

Dongguan Yyi Technology is a professional OEM plastic parts & Metal Fabrication factory located in Dongguan, China and specialize in this field since 2011. Our main business is 3D printing service, vacuum casting,CNC machining, plastic injection molding,and sheet matal Fabrication.Own over 200 professional staff and 2300+sets printing devices ,CNC machining center,drilling and milling machine etc.With these machines and experienced employees, we are able to provide strong guarantee for precision and strength parts. we stive to exceed our customer's expectation in all aspects of product manufacturing process, and recognize our great responsiblities to our customers,employees, suppiers and society. we keep adopting advanced production facilities to improve efficiency and ensure high and stable qualtity, and further reduce the production cost. The objective is to create reliable,viable and affordable prototype,plastic and metal parts and fast sample service for every industry

Why Choose YYI Tech

Whether you need new product development verification or personalized customization, YYI Tech can meet your needs

Integrated solution

Integrated solution

One-stop service

One-stop service

Powerful service capability

Powerful service capability

Fast delivery time

Fast delivery time

High quality & Excellent price

High quality & Excellent price

Data confidentiality

Data confidentiality

FAQ