Medical

Medical - On demand rapid manufacturing

In recent years, there has been a lot of research on the application of RP technology in the medical field. Based on medical imaging data, the use of RP technology to create human organ models has great application value for surgical procedures. These models provide assistance to researchers, implant designers, and surgeons who want to observe the bone structure of patients without surgery. These technologies are applied in many specialties such as neurosurgery, neurosurgery, oral surgery, plastic surgery, and head and neck surgery to assist surgeons in surgical planning, which is impossible without physical models.

What problems has YYI TECH solved in the field of medical manufacturing?

● Development of new medical device products

Various types of testing and assembly components can be quickly and economically manufactured, replacing the high cost and long cycle of traditional mold making for mass production.

● Oral restoration

Digital scanning quickly and accurately obtains patient oral data, providing more accurate and matching data support for orthopedic instruments related to dentistry and plastic surgery; Meanwhile, 3D printing technology can provide patients with highly personalized dental implants and models.

● Rehabilitation aids

Realize functional integration and lightweight design, achieve rapid customized manufacturing, improve wearing comfort and aesthetics

● Preoperative model

Quickly and accurately printing out relevant tissue or organ models before surgery facilitates doctor-patient communication and the development of medical plans, and can also improve the success rate of surgery.

Application of rapid prototyping in medical industry

■ Model of Medical Devices

■ Design, trial production, and testing of medical devices in the medical industry

■ The materialization of CT scan information

■ Surgical simulation

■ Preparation of human bones and joints.

■ Human body model, complete complex organs such as kidneys, liver, heart, etc

■ Oral restoration

■ Surgical guide plate

■ Medical implants

■ Customized medical implants, such as customized prosthetics, etc

Classic case we have done

3D printing medical head model

● Customer requirements:

Display model of medical skull, transparent parts need to see the interior, and partially made of medical grade 3D printing materials

● Production difficulties:

The difficulty of polishing and painting transparent parts is high, and there are few choices of medical grade materials, which is expensive

● Quantity: 1set

● Material: Resin+Peek

● Process: SLA 3D printing+FDM 3d printing

● Delivery time: 7days

Our Production solution:

According to the customer's requirements, we have selected a combination of SLA transparent resin and FDM Peek material. The difficulty of transparent resin lies in post-processing, and we have adopted a disassembly and splicing scheme to achieve full transparency. The assembly of PEEK and transparent parts is done by riveting

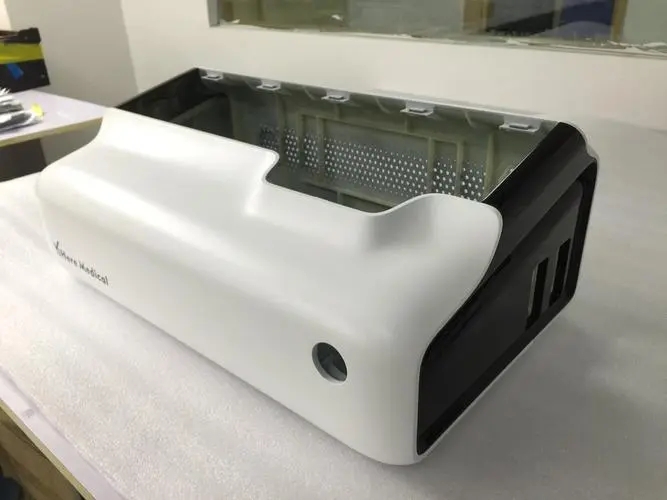

Injection molding RF beauty device plastic shell

● Customer requirements:

Need to produce 1000 sets of small batch medical shells for market promotion and verification, with a smooth surface requirement

● Production difficulties:

The quantity is small, and the price of opening a formal steel mold is expensive

● Quantity: 1000sets

● Material: PC+ABS

● Process: Injection molding

● Delivery time: 40days

Our Production solution:

According to requirements, we have adopted a simple metal mold (with a lifespan difference of only 10000 times compared to a formal steel mold), which effectively reduces mold costs without compromising product quality

Full color polyjet 3D print medical heart model

● Customer requirements:

The surface needs to as same as the real heart

● Production difficulties:

The quantity is small and the color is difficult to adjust

● Production Solution:

The surface color should be realistic, and small quantity and complex structure. It is recommended to use full-color polyjet 3D printing, which can be printed as a whole, and 10 pieces can be printed and shipped in 7 days

● Quantity: 10pcs

● Material: Resin

● Process: Polyjet 3d printing process

● Delivery time: 7days