Medical Beauty Parts Mold Injection

How to solve the problem of product deformation by injection molding?

Deformation of injection molded products is a common and difficult problem. To solve this problem, from the perspective of machine adjustment, the feasibility is not very high. The deformation problem mainly needs to be solved from the perspective of mold design. The specific causes and solutions of deformation are summarized as follows:

1. When deformation is caused by injection molding conditions, YYI TECH factory eliminates stress by reducing injection pressure, increasing mold temperature to make the mold uniform, and increasing resin temperature or using annealing methods.

2. When poor demolding causes stress deformation, we use methods such as increasing the number or area of push rods, and correcting the demolding slope.

3. When the cooling is uneven or the cooling time is insufficient for deformation, adjust the cooling method and extend the cooling time. Setting up cooling circuits as close to the deformation as possible can also improve the deformation problem.

4. For the deformation caused by molding shrinkage, it is necessary to modify the design of the mold. Among them, the most important thing is to pay attention to making the wall thickness of the product consistent. Sometimes, in unavoidable circumstances, it is necessary to measure the deformation of the product, adjust the mold in the opposite direction, and correct it.

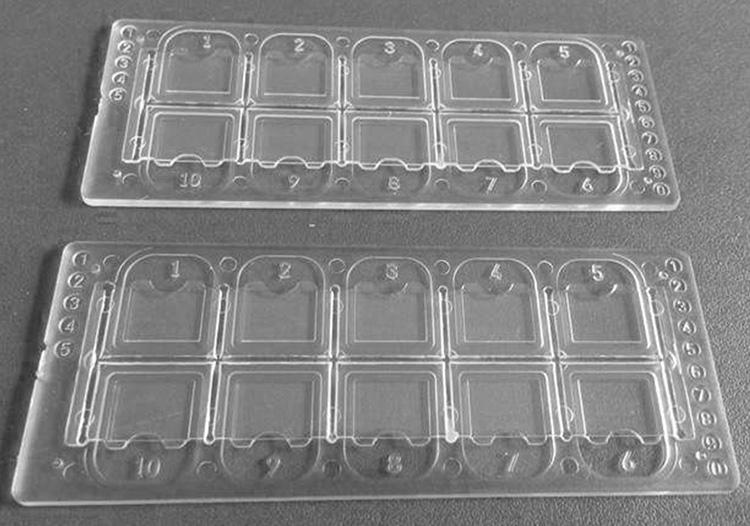

Thin wall medical parts injection molding

Size: customized by customers

Product materials: PE/PP/PC/PS/peek/ppsu, etc.

Quality system: ISO 13485 medical certification.

Product uses: syringes, test tubes, medical consumables, medical devices, in vivo implants, etc.

Application areas: medical, food, biological consumables industry, etc

Hemocytometer transparent medical parts Mold injection

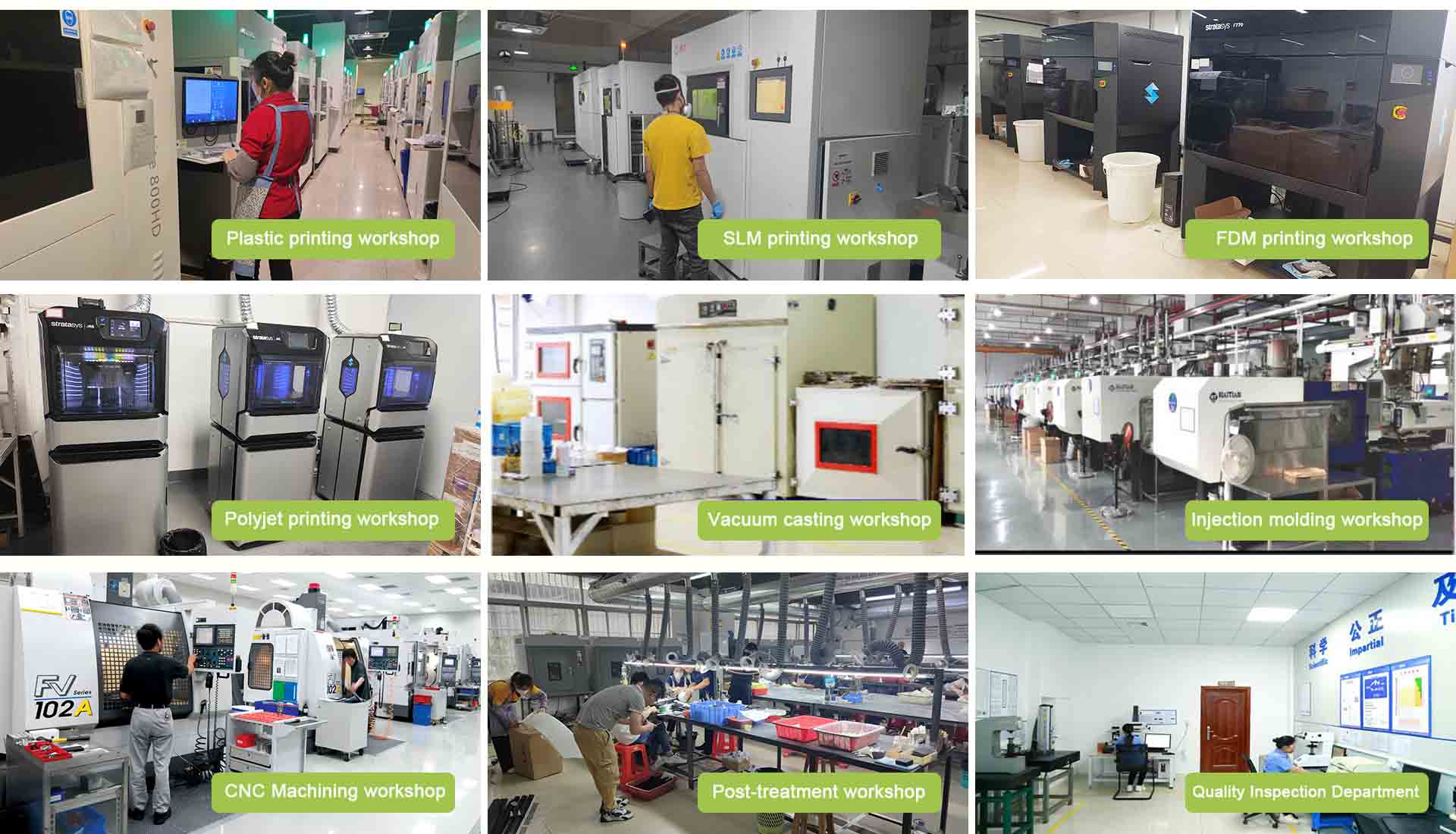

YYI Tech Factory and equipment display

300+sets rapid prototyping equipment, complete materials, complete processes, and comprehensive equipment to meet your various customization needs

About YYI Tech

A professional one-stop rapid prototyping manufacturer

Dongguan Yyi Technology is a professional OEM plastic parts & Metal Fabrication factory located in Dongguan, China and specialize in this field since 2011. Our main business is 3D printing service, vacuum casting,CNC machining, plastic injection molding,and sheet matal Fabrication.Own over 200 professional staff and 2300+sets printing devices ,CNC machining center,drilling and milling machine etc.With these machines and experienced employees, we are able to provide strong guarantee for precision and strength parts. we stive to exceed our customer's expectation in all aspects of product manufacturing process, and recognize our great responsiblities to our customers,employees, suppiers and society. we keep adopting advanced production facilities to improve efficiency and ensure high and stable qualtity, and further reduce the production cost. The objective is to create reliable,viable and affordable prototype,plastic and metal parts and fast sample service for every industry

Why Choose YYI Tech

Whether you need new product development verification or personalized customization, YYI Tech can meet your needs

Integrated solution

Integrated solution

One-stop service

One-stop service

Powerful service capability

Powerful service capability

Fast delivery time

Fast delivery time

High quality & Excellent price

High quality & Excellent price

Data confidentiality

Data confidentiality

FAQ