MJF 3D Printing Service: Customization & Small-Batch Production

▸ Low-Cost Flexibility: Start production at $14/piece with 1pc MOQ, ideal for prototypes to 300-unit batches

▸ Industrial-Grade Nylon: Use HP PA 12 (standard/glass-filled) for chemical-resistant, durable parts with ±0.3mm dimensional accuracy

▸ Rapid Turnkey Service: Submit CAD/BIM/STL files for instant quotes and production in 4-12 workdays

▸ Customized Solutions: Optimize designs for functional prototypes, end-use automotive components, or medical tools

▸ Post-Processing Included: Achieve smooth surfaces (Ra 0.6μm) with ultrasonic cleaning and curing

How does MJF Plastic 3D printing work?

The principle of MJF rapid prototyping:

First lay a layer of powder, then spray the flux, and at the same time, spray a fine agent to ensure the fineness of the printed object edges, and then apply a heat source to it. This layer is considered completed,until the 3D object is completed.

Suitable for use as functional test pieces and end product components. There are many applications in medical devices, automotive parts, aerospace, home appliances, and other fields.

We have complete sets of MJF equipment, HP 3D

printers, building units, and processing stations

|

|

| Laying powder | Hot nozzle sprays reagents and heats up |

Advantages of MJF 3D printing rapid prototyping:

The printing of MJF is 10 times faster than traditional selective laser sintering (SLS) and melt deposition molding (FDM) technologies, and it does not sacrifice the precision of the components,which is suitable for producing sturdy, high-quality components at extremely low unit costs

(1)Fast processing speed.

MJF is 10 times faster than traditional selective laser sintering (SLS) and melt deposition molding (FDM) technologies, and it does not sacrifice the precision of the components.

Printing gear as an example as following figure: also took 3 hours,The FDM on the left only printed 36pcs, and the SLS in the middle printed 79pcs, but the HP MJF printed 1000pcs

Printing speed of MJF,SLS and FDM

Printing speed of MJF,SLS and FDM

(2)MJF printed parts with high quality

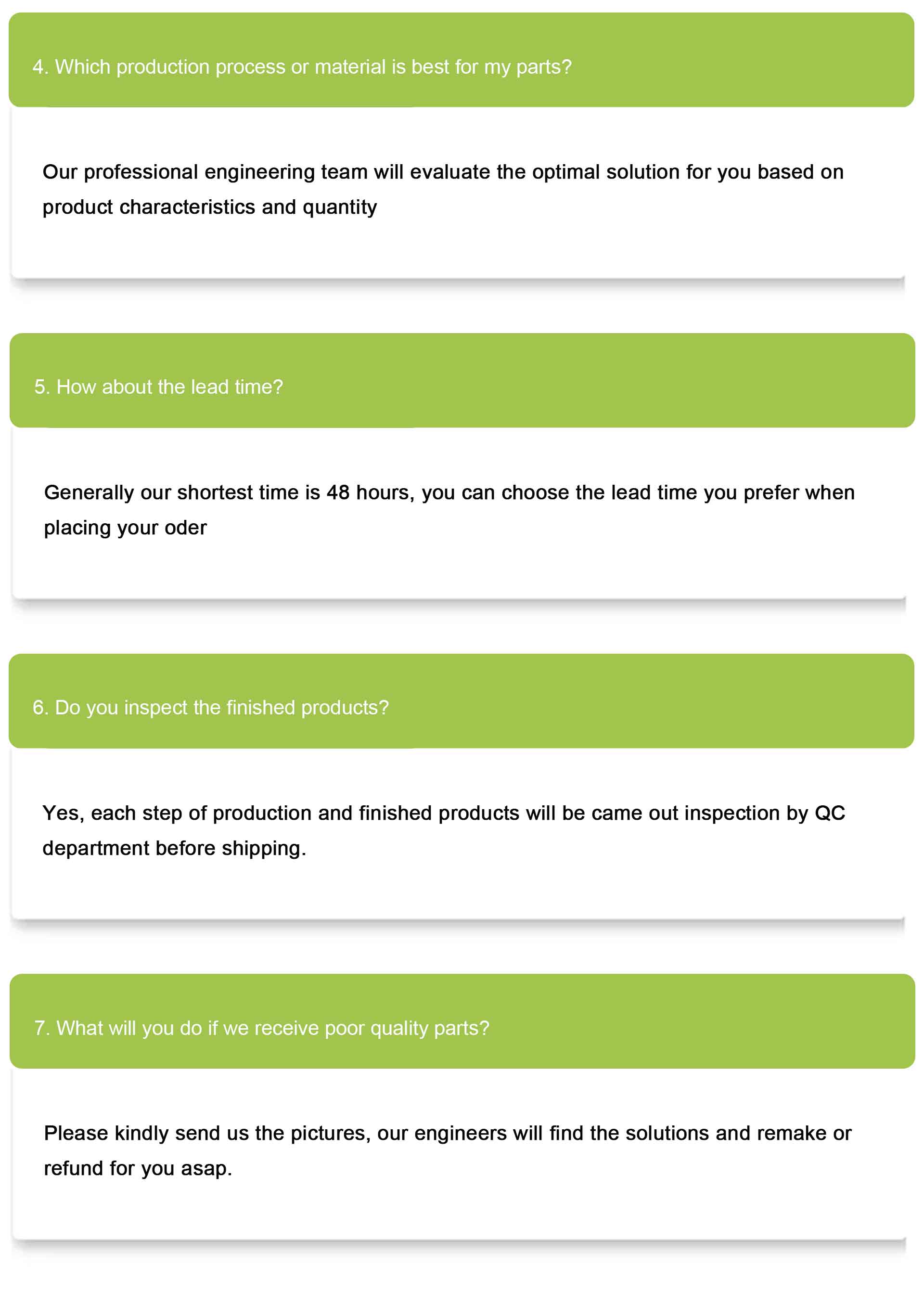

Comprehensive performance, excellent mechanical performance, suitable for functional parts.Here is a small verification, using a printed elliptical structure to lift a car. This structure only takes 30 mins to print, weighs 113g, but can lift up to 5 tons of weight.

Load bearing test of MJF parts

Load bearing test of MJF parts

(3)Surface treatment advantages

Good surface sealing, relatively easy to polish and spray compared to SLS printing materials

(4)Reduce costs and shorten manufacturing cycles.

MJF has high reusability, and the reusability of the remaining powder

What materials can you choose for MJF plastic 3D printing?

The MJF process printing material is nylon, which has high strength, good toughness, and can withstand temperatures of 100-120 ℃. The printing accuracy of this process is about ± 0.15 millimeters, and the printed product has a tolerance value of 2.5

|

Characteristic |

Material |

Color |

Tolerance |

Max Build Size(mm) |

|

Good toughness, suitable for workpieces with certain toughness for assembly |

PP |

Dark gray |

±0.2mm |

380*380*280 |

|

Soft rubber, elastic |

TPU |

Dark gray |

±0.2mm |

380*380*280 |

|

Good strength and toughness |

Nylon pa12 |

Dark gray |

±0.2mm |

380*380*280 |

Case studies of MJF Plastic 3D printing:

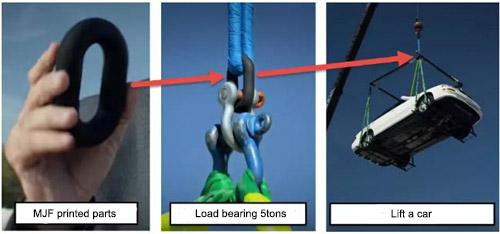

YYI Tech Factory and equipment display

300+sets rapid prototyping equipment, complete materials, complete processes, and comprehensive equipment to meet your various customization needs

About YYI Tech

A professional one-stop rapid prototyping manufacturer

Dongguan Yyi Technology is a professional OEM plastic parts & Metal Fabrication factory located in Dongguan, China and specialize in this field since 2011. Our main business is 3D printing service, vacuum casting,CNC machining, plastic injection molding,and sheet matal Fabrication.Own over 200 professional staff and 2300+sets printing devices ,CNC machining center,drilling and milling machine etc.With these machines and experienced employees, we are able to provide strong guarantee for precision and strength parts. we stive to exceed our customer's expectation in all aspects of product manufacturing process, and recognize our great responsiblities to our customers,employees, suppiers and society. we keep adopting advanced production facilities to improve efficiency and ensure high and stable qualtity, and further reduce the production cost. The objective is to create reliable,viable and affordable prototype,plastic and metal parts and fast sample service for every industry

Why Choose YYI Tech

Whether you need new product development verification or personalized customization, YYI Tech can meet your needs

Integrated solution

Integrated solution

One-stop service

One-stop service

Powerful service capability

Powerful service capability

Fast delivery time

Fast delivery time

High quality & Excellent price

High quality & Excellent price

Data confidentiality

Data confidentiality

FAQ