Plastic shell injection molded parts

How to solve defects in injection molded products?

During the molding process of injection mold shells, various product defects are encountered, such as product wear, deformation, burrs, fractures, weld marks, and other issues. So how should we solve these problems when encountering them?

1. Wear and tear: The demolding slope of the injection mold shell is too small, making demolding difficult, the verticality is not good, there are processing residues at the worn areas, such as burrs at the corners of the mold cavity after grinding, excessive roughness, etc., which are easy to solve. The bubble temperature is too low or too high, the wall thickness is uneven or too thick, the moisture content is too high, the solvent or volatile substances are contained, the pressure is too high, the exhaust is not smooth, and the injection cycle is too long, causing the material to decompose in the barrel.

2. Deformation: When designing molds, factors such as product deformation during mold release, mold temperature, material temperature, high temperature during mold release, insufficient holding time, and residual stress, as well as uneven wall thickness and shrinkage of the product, improper gate and top rod positions, and mold sticking, must be considered. Flying edge: The locking pressure cannot withstand the injection pressure, the template deforms, the closure is not tight, the temperature is too high, the cavity gap is too large, and the position is offset.

3. Fracture: Excessive material return or filling, too small or insufficient top rod, too fast top speed, too low material temperature, mold sticking, vacuum state caused by too small gap, etc. Insufficient preheating of embedded parts can also cause cracks. A few products need to be annealed to relieve stress. Weld marks: Weld marks are difficult to avoid when multiple cores are broken. Reasonable control of temperature and injection speed, as well as the design of gate and exhaust overflow positions, are necessary to improve the appearance of the injection mold shell.

Pet product shell-rapid prototyping plastic injection molding

Receiver housing-rapid prototyping plastic injection molding

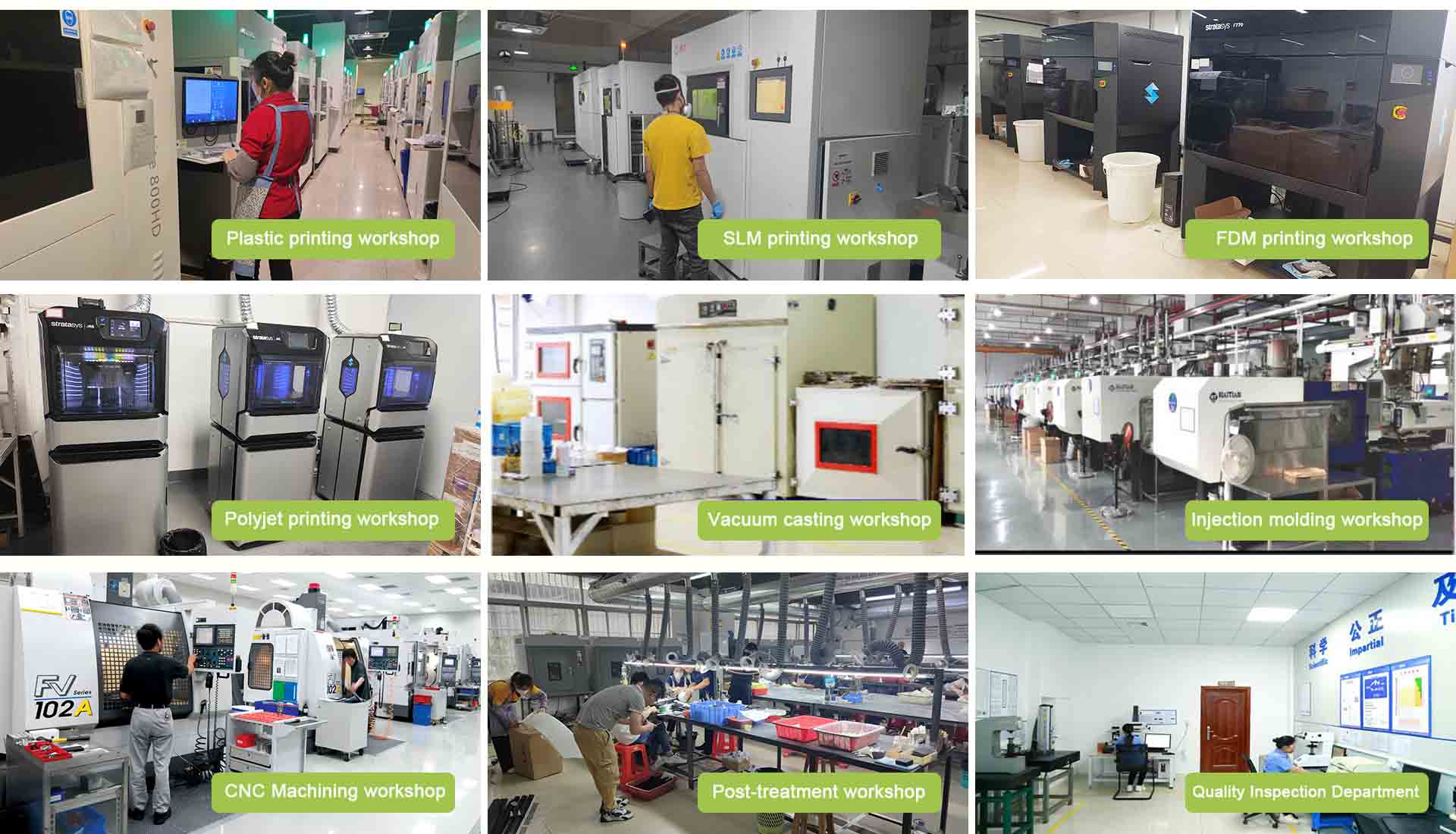

YYI Tech Factory and equipment display

300+sets rapid prototyping equipment, complete materials, complete processes, and comprehensive equipment to meet your various customization needs

About YYI Tech

A professional one-stop rapid prototyping manufacturer

Dongguan Yyi Technology is a professional OEM plastic parts & Metal Fabrication factory located in Dongguan, China and specialize in this field since 2011. Our main business is 3D printing service, vacuum casting,CNC machining, plastic injection molding,and sheet matal Fabrication.Own over 200 professional staff and 2300+sets printing devices ,CNC machining center,drilling and milling machine etc.With these machines and experienced employees, we are able to provide strong guarantee for precision and strength parts. we stive to exceed our customer's expectation in all aspects of product manufacturing process, and recognize our great responsiblities to our customers,employees, suppiers and society. we keep adopting advanced production facilities to improve efficiency and ensure high and stable qualtity, and further reduce the production cost. The objective is to create reliable,viable and affordable prototype,plastic and metal parts and fast sample service for every industry

Why Choose YYI Tech

Whether you need new product development verification or personalized customization, YYI Tech can meet your needs

Integrated solution

Integrated solution

One-stop service

One-stop service

Powerful service capability

Powerful service capability

Fast delivery time

Fast delivery time

High quality & Excellent price

High quality & Excellent price

Data confidentiality

Data confidentiality

FAQ