Laser Sintering 3D Printing Service: Robust & High-Performance Prototyping Delivered in 24 Hours

Transform your digital designs into production-ready prototypes with our industrial-grade Laser Sintering 3D Printing Service, engineered for durability and rapid innovation across multiple industries.

Diverse Material Selection

▸ Leverage an extensive range of high-performance materials such as nylon, carbon-fiber composites , and glass-filled polymers for superior strength and versatility.

▸ Utilize specialized additives to boost thermal stability and chemical resistance for critical applications.

Precision & Structural Integrity

▸ Achieve fine detail with layer resolutions as low as 50μm , ensuring components meet rigorous performance and safety standards.

▸ Optimized support systems preserve intricate geometries and maintain design accuracy throughout the build process.

▸ No minimum order required—easily scale from a single prototype to mass production runs.

▸ Compatible with popular design file formats ( STL , OBJ , STEP ) to seamlessly integrate into your workflow.

▸ Aerospace : Lightweight yet durable components engineered for flight testing and performance.

▸ Automotive : High-strength parts designed for demanding operational conditions in performance vehicles.

▸ Consumer Goods : Resilient, ergonomic designs ideal for everyday products and rapid market validation.

▸ Post-Processing Options : Choose from advanced finishing techniques—including polishing, dyeing, and sandblasting—to elevate both aesthetics and functionality.

▸ Sustainable Production : Eco-friendly processes that minimize waste while delivering high-quality prototypes.

Plastic & metal rapid prototype

What's rapid prototyping?

Prototype is a functional template made based on the appearance or structural drawings of a product, without the need for a mold, to check the rationality of its appearance or structure.

When need Plastic & metal rapid prototype?

Usually, newly developed or designed products require a prototype, which is the first step in verifying the feasibility of the product. It is the most direct and effective way to identify the defects, deficiencies, and drawbacks of the designed product, so as to make targeted improvements to the defects until the shortcomings cannot be found from individual prototype samples. At this point, it is usually necessary to conduct small-scale trial production to identify deficiencies in the batch and improve them. The designed products are generally not perfect or even unusable. Once there are defects in direct production, they will be completely scrapped, greatly wasting manpower, material resources, and time; However, in general, the prototype is a small number of samples, with a short production cycle and less manpower and material resources. It quickly identifies the shortcomings in product design and improves it, providing sufficient basis for product standardization and mass production.

● Inspection of structural design

Because the prototype can be assembled, it can intuitively reflect the rationality of the structure and the difficulty of installation. Facilitate early detection and resolution of issues.

● Inspection of appearance design

The prototype is not only visible, but also touchable. It can intuitively reflect the designer's ideas in the form of physical objects, preventing the disadvantage of "drawing beautiful but making unattractive". Therefore, the manufacturing of prototype models is essential in the process of new product development and product shaping.

● Product launch in advance

Due to the advanced manufacturing of plastic and metal prototype models, you can use the prototype to promote the product and even prepare for sales and production before the mold is developed, in order to seize the market early.

● Avoiding the waste and danger of directly opening molds

Due to the high cost of mold manufacturing, relatively large molds are worth hundreds of thousands or even millions. If unreasonable layout or other problems are found during the mold opening process, their loss can be imagined. The manufacturing of prototype models can prevent such loss and reduce the risk of mold opening.

Rapid prototyping Technology

Based on customer needs, we comprehensively and flexibly utilize various processes to provide you with cost-effective fast samples

Rapid Industiral 3D print prototyping serive

Rapid Industiral 3D print prototyping serive

Rapid CNC machining service

Rapid CNC machining service

Rapid sheet metal fabracation

Rapid sheet metal fabracation

Prototype material:

(1). Plastic rapid prototyping

Comprehensive materials available with high selectivity, including soft plastic, hard plastic, and transparent material: ABS, PP,PC,Nylon,peek,tpu,pc,resin,pom,pmma,etc.

(2). Metal rapid prototyping

Aluminum,stainless steel,copper etc for choice.We will recommend the most suitable materials for you based on the customer's product performance requirements, price.

Case studies of plastic rapid prototyping:

Case studies of metal rapid prototyping:

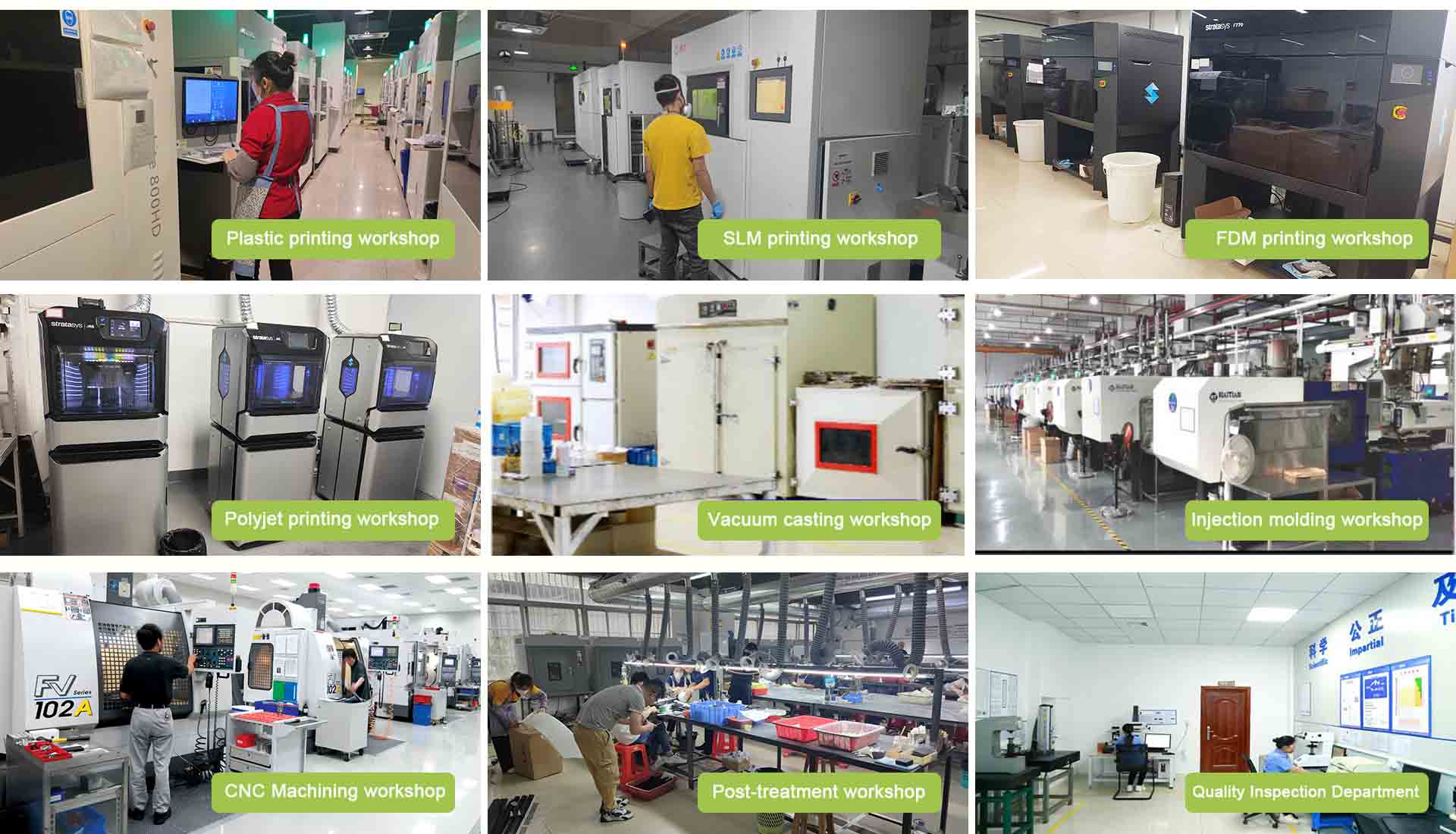

YYI Tech Factory and equipment display

300+sets rapid prototyping equipment, complete materials, complete processes, and comprehensive equipment to meet your various customization needs

About YYI Tech

A professional one-stop rapid prototyping manufacturer

Dongguan Yyi Technology is a professional OEM plastic parts & Metal Fabrication factory located in Dongguan, China and specialize in this field since 2011. Our main business is 3D printing service, vacuum casting,CNC machining, plastic injection molding,and sheet matal Fabrication.Own over 200 professional staff and 2300+sets printing devices ,CNC machining center,drilling and milling machine etc.With these machines and experienced employees, we are able to provide strong guarantee for precision and strength parts. we stive to exceed our customer's expectation in all aspects of product manufacturing process, and recognize our great responsiblities to our customers,employees, suppiers and society. we keep adopting advanced production facilities to improve efficiency and ensure high and stable qualtity, and further reduce the production cost. The objective is to create reliable,viable and affordable prototype,plastic and metal parts and fast sample service for every industry

Why Choose YYI Tech

Whether you need new product development verification or personalized customization, YYI Tech can meet your needs

Integrated solution

Integrated solution

One-stop service

One-stop service

Powerful service capability

Powerful service capability

Fast delivery time

Fast delivery time

High quality & Excellent price

High quality & Excellent price

Data confidentiality

Data confidentiality

FAQ