PolyJet 3D Printing Service: Multi-Material & Full-Color Prototyping Delivered in 24 Hours

Transform your digital designs into high-precision physical prototypes with our industrial-grade PolyJet 3D printing solutions, optimized for rapid innovation across industries:

▸ Ultra-Fast Delivery

Achieve end-to-end production from file submission to finished parts in 24 hours, enabling seamless iteration for complex assemblies without traditional tooling delays

▸ Unlimited Material & Color Combinations

• Integrate 6 material properties (rubber-like elasticity, rigid plastics, transparent resins, etc.) in a single print

• Access 500,000+ Pantone colors and gradient textures, ideal for lifelike medical organ models with vascular-level color accuracy

▸ Industrial-Grade Precision

• 16μm ultra-thin layer resolution supports microfluidic chips, 0.1mm thin-walled structures, and surfaces with Ra 0.6μm smoothness for direct assembl

• Water-soluble support materials ensure complex geometries retain pristine details post-processing

▸ Zero-Barrier Flexible Production.

• No minimum order quantity—scale from 1-unit prototypes to 1,000+ batch production

• Compatible with BIM/CAD/STL files and automated support generation

▸ Industry-Specific Solutions

• Medical: Biocompatible surgical guides and dental models

• Automotive: Heat-resistant transparent materials for headlight prototypes and fluid-testing components

• Architecture: Full-color gradient models showcasing composite material lighting effects

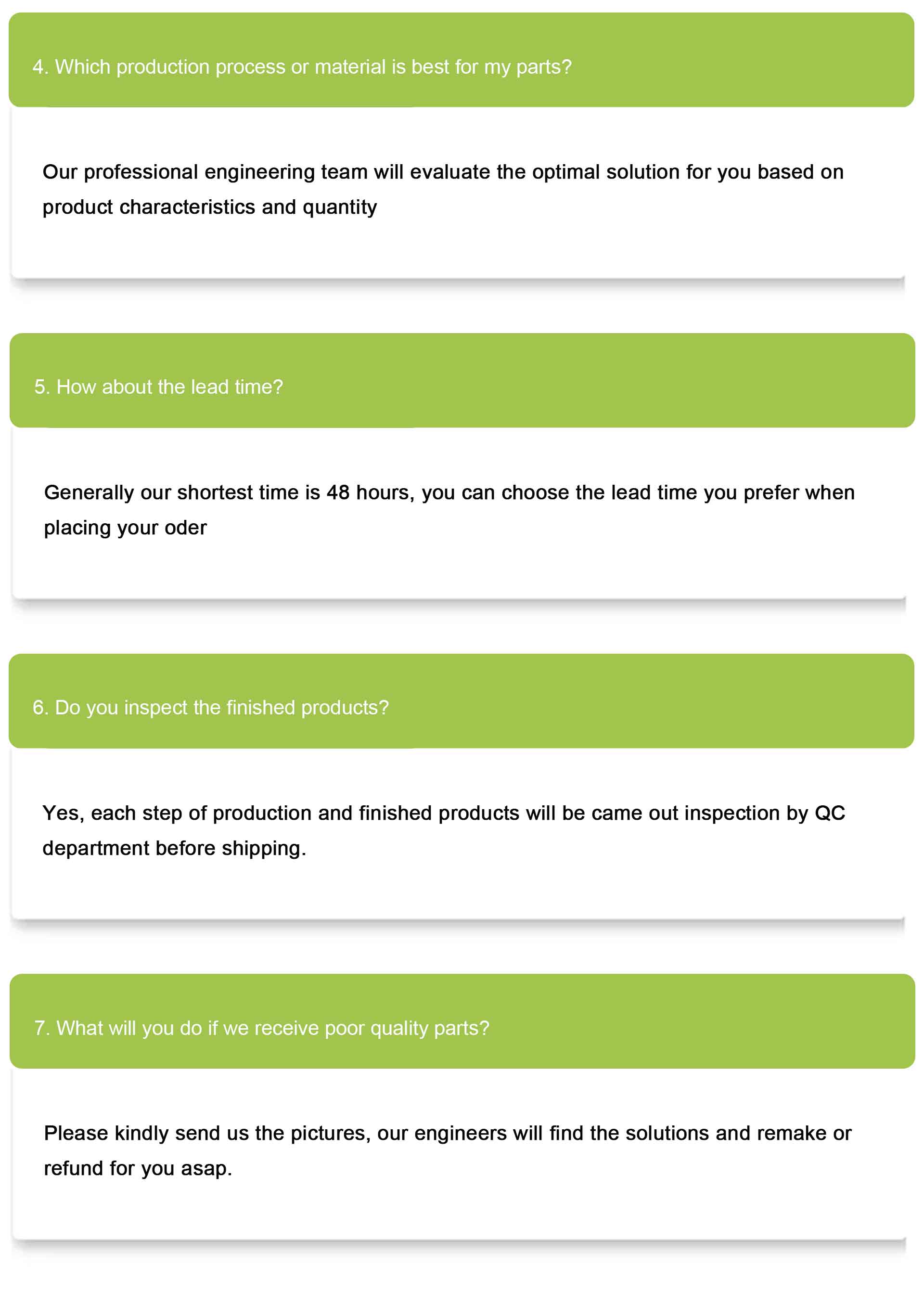

How does Polyjet Plastic 3D printing work?

The principle of PolyJet rapid prototyping:

PolyJet 3D printing sprays a liquid photopolymer layer onto the construction tray and immediately cures it with ultraviolet light. Thin layer accumulation molding until an accurate 3D model or prototype is formed.

PolyJet can achieve color and multi material integration in a single printing process, creating prototypes that are close to real products, and can also be used to print rapid molds and validate product designs.

|

|

| Stratasys Polyjet printer | The Object PolyJet process |

Advantages of polyjet full color 3D printing rapid prototyping:

Featuring 480000 color spaces. Complex colors such as matte, glossy, leather, wood grain, and stone texture can be easily achieved

(1) PolyJet can create fine prototypes with smooth surfaces, presenting the aesthetic of the final product.

(2) PolyJet can manufacture precise molds, drill dies, fixtures, and other manufacturing tools.

(3) PolyJet can handle complex shapes and details, presenting exquisite features.

(4) PolyJet can apply the widest range of colors and material types to a single model, achieving unparalleled efficiency and achieving more realistic colors.

What materials can you choose for polyjet full color plastic 3D printing?

|

Characteristic |

Material |

Color |

Tolerance |

Max Build Size(mm) |

|

Realistic prototype |

Resin+SUP710™ |

Full color |

±0.1mm |

140*200*190 |

Case studies of polyjet full color Plastic 3D printing:

Suitable for medical teaching, toys, figurines, portraits, color personalized customization and other application scenarios.

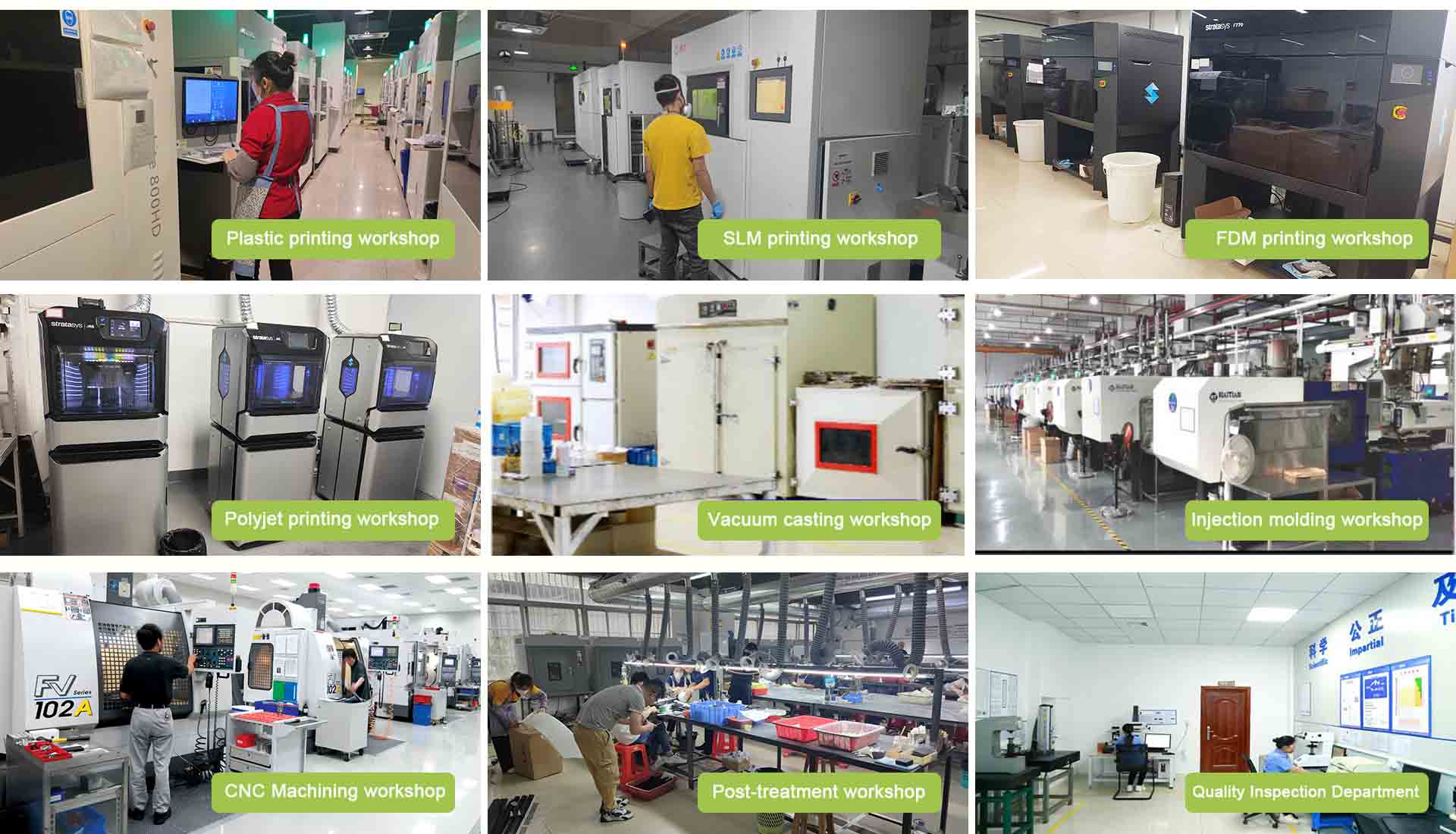

YYI Tech Factory and equipment display

300+sets rapid prototyping equipment, complete materials, complete processes, and comprehensive equipment to meet your various customization needs

About YYI Tech

A professional one-stop rapid prototyping manufacturer

Dongguan Yyi Technology is a professional OEM plastic parts & Metal Fabrication factory located in Dongguan, China and specialize in this field since 2011. Our main business is 3D printing service, vacuum casting,CNC machining, plastic injection molding,and sheet matal Fabrication.Own over 200 professional staff and 2300+sets printing devices ,CNC machining center,drilling and milling machine etc.With these machines and experienced employees, we are able to provide strong guarantee for precision and strength parts. we stive to exceed our customer's expectation in all aspects of product manufacturing process, and recognize our great responsiblities to our customers,employees, suppiers and society. we keep adopting advanced production facilities to improve efficiency and ensure high and stable qualtity, and further reduce the production cost. The objective is to create reliable,viable and affordable prototype,plastic and metal parts and fast sample service for every industry

Why Choose YYI Tech

Whether you need new product development verification or personalized customization, YYI Tech can meet your needs

Integrated solution

Integrated solution

One-stop service

One-stop service

Powerful service capability

Powerful service capability

Fast delivery time

Fast delivery time

High quality & Excellent price

High quality & Excellent price

Data confidentiality

Data confidentiality

FAQ