Reaction Injection Moulding(RIM)

How does Reaction Injection Moulding work?

Reaction Injection Moulding(RIM), is the process of mixing two component polyurethane materials and injecting them into a rapid mold at room temperature and low pressure. It is formed through chemical and physical processes such as material polymerization, cross-linking, and curing.

RIM has relatively advantages in making large components with relatively simple structures. However, one thing is certain: the performance of RIM materials is relatively much better than that of vacuum injection materials. Whether it's hardness. Both toughness and temperature resistance are much superior

Features of Reaction Injection Moulding?

| Available material | ABS Alike,PP Alike, Rubber alike |

| Available Mold | Aluminum mold,cast aluminum mold,resin mold |

| Tolerance | ±0.20mm/100mm |

| Pouring sample thickness | 4~6mm,Large workpiece 10mm |

| Large casting workpiece |

2000mm x 1200mm x 1000mm,10kg |

| Application | Small batch production, large panels with simple structures and products with uneven wall thickness |

| Available industry |

Automotive modification parts, medical device casings, industrial equipment casings, furniture with free design, etc. |

Advantages of Reaction Injection Moulding:

1. Low mold cost, short mold opening time, and rapid market expansion

① Low injection pressure, low-cost materials available for mold;

② Aluminum alloy, cast aluminum, and epoxy resin are available for molds

2. Flexible design

① Different part wall thicknesses can be used on the same part,comparable to structural components

② The surface of the parts will not produce shrinkage marks, no internal stress, and no deformation;

3. The density, hardness, and bending modulus of the material can be adjusted to meet different needs

① Density range: 200~1200 kg/m ³

② Hardness range: Shore A 40~Shore D 80

③ Bending modulus: 400~2000Mpa/m ²

4. Stable structure, easy to use and durable, good encapsulation ability, and strong component encapsulation ability

① Encapsulation can reduce assembly costs and also solve problems of parts damage and sealing.such as medical instruments.

What kind of parts are suitable for RIM process?

If more than 4 points that meet the following characteristics, you can consider RIM technology

1.Parts updates and replacements are relatively fast

2.Circumference of parts exceeding 2000mm and height exceeding 100mm

3.Parts with large volume and need good rigidity, but the weight cannot increase

4.Parts annual quantity is less than 2000 sets

5.High requirements for parts appearance expressiveness

6.Short product design cycle

7.Limited investment in mold costs

8.Market situation of parts is unclear

9.Parts assembly is complex, hope to reduce the assembly process

10.Other processes cannot complete part wrapping

11.Strong interchangeability of parts

Application of Reaction Injection Moulding:

RIM is suitable for small-scale trial production. Mainly used in the automotive and medical industries. It can an only produce large-sized products with simple structures and plastic products with uneven wall thickness. This type is mainly used for medical vehicle casings, instrument casings, reagent equipment casings, car bumpers, car engine covers, etc.

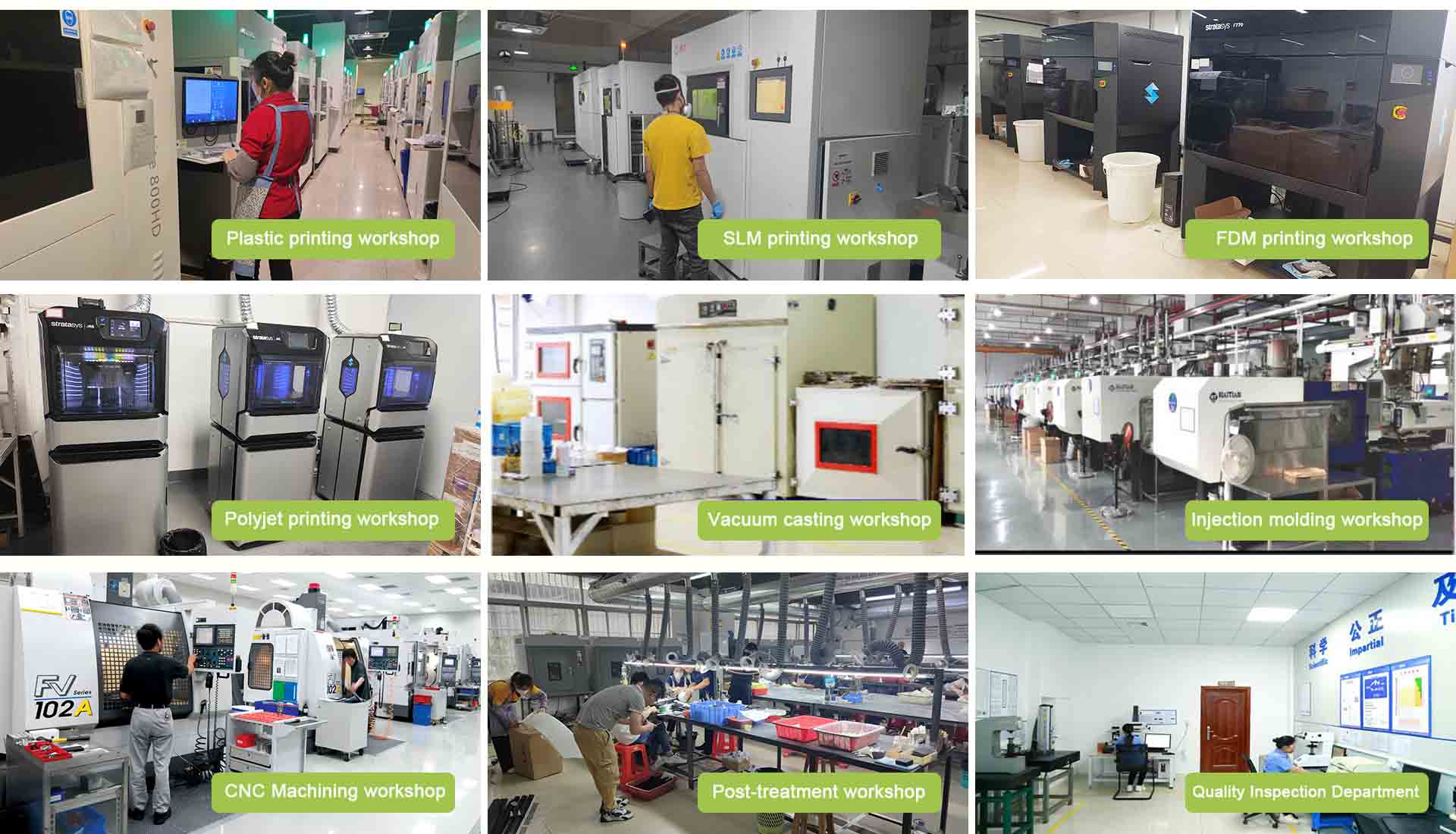

YYI Tech Factory and equipment display

300+sets rapid prototyping equipment, complete materials, complete processes, and comprehensive equipment to meet your various customization needs

About YYI Tech

A professional one-stop rapid prototyping manufacturer

Dongguan Yyi Technology is a professional OEM plastic parts & Metal Fabrication factory located in Dongguan, China and specialize in this field since 2011. Our main business is 3D printing service, vacuum casting,CNC machining, plastic injection molding,and sheet matal Fabrication.Own over 200 professional staff and 2300+sets printing devices ,CNC machining center,drilling and milling machine etc.With these machines and experienced employees, we are able to provide strong guarantee for precision and strength parts. we stive to exceed our customer's expectation in all aspects of product manufacturing process, and recognize our great responsiblities to our customers,employees, suppiers and society. we keep adopting advanced production facilities to improve efficiency and ensure high and stable qualtity, and further reduce the production cost. The objective is to create reliable,viable and affordable prototype,plastic and metal parts and fast sample service for every industry

Why Choose YYI Tech

Whether you need new product development verification or personalized customization, YYI Tech can meet your needs

Integrated solution

Integrated solution

One-stop service

One-stop service

Powerful service capability

Powerful service capability

Fast delivery time

Fast delivery time

High quality & Excellent price

High quality & Excellent price

Data confidentiality

Data confidentiality

FAQ