The qualified rate of high-precision sheet metal processing products is as high as 99.6%

Sheet metal final goods

The three key processes in sheet metal factories are generally drilling, punching/drilling, and sheet metal bending. Generally, metal sheets are made by hand or stamped with molds to undergo plastic deformation, resulting in the desired shape or specifications. Then, more complex components such as chimneys, white iron furnaces, and car casings are produced through welding or small-scale mechanical processing.

Sheet metal processing utilizes sheet metal to make chimneys, stainless steel barrels, oil storage tanks, ventilation ducts, bend pipe sizes, circular areas, and pipe shapes. The key process flows include cutting, bending, bending forming, electric welding, riveting, etc.

Sheet metal parts are thin metal products, which means components that can be produced and processed through stamping molds, bending, stretching, and other methods. They roughly define the parts that will not change in thickness during production and processing. Matching products include forged, forged, and machined components, such as metal sheets for the exterior of automobiles and stainless steel plates for cooking equipment.

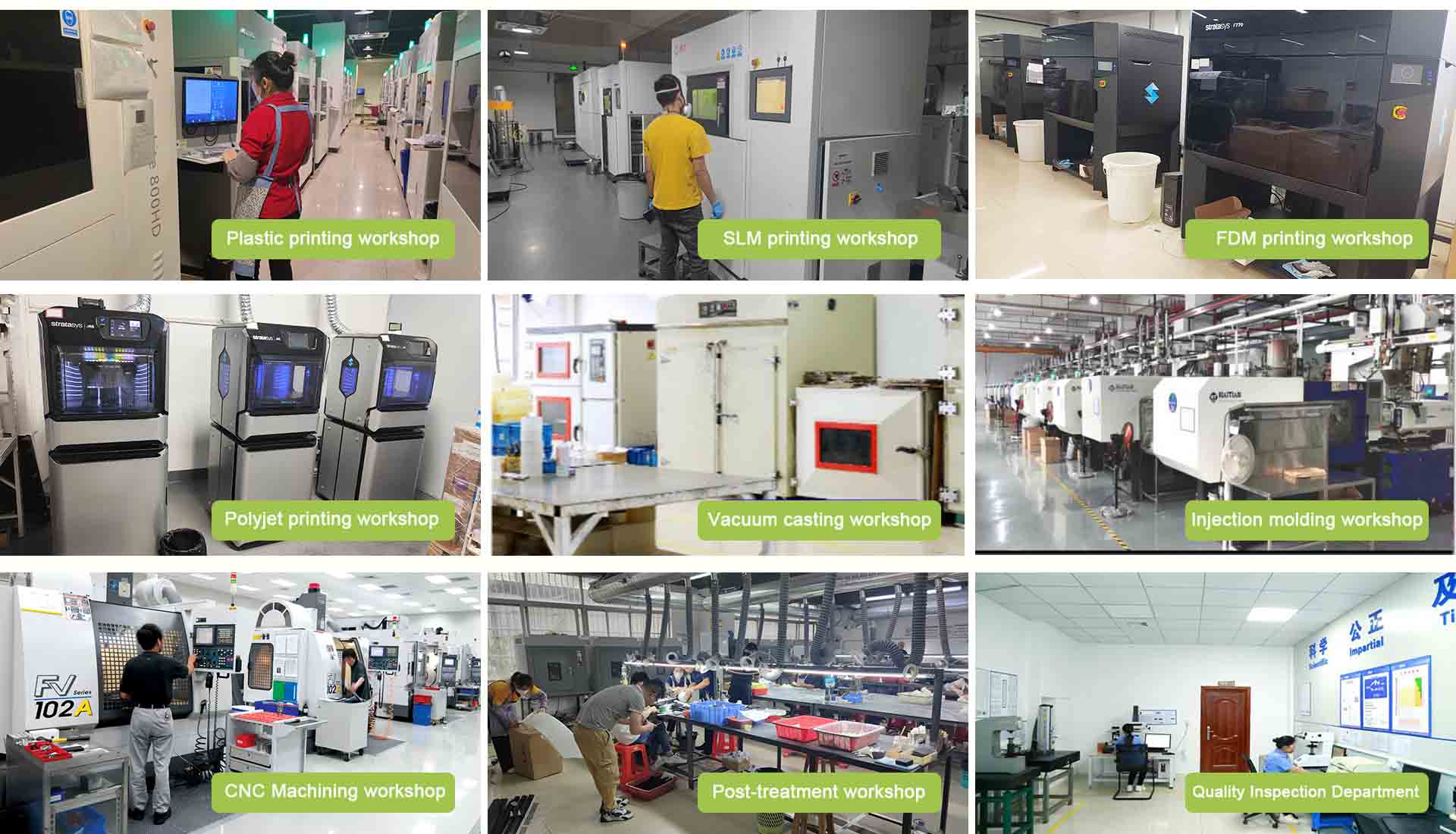

YYI Tech Factory and equipment display

300+sets rapid prototyping equipment, complete materials, complete processes, and comprehensive equipment to meet your various customization needs

About YYI Tech

A professional one-stop rapid prototyping manufacturer

Dongguan Yyi Technology is a professional OEM plastic parts & Metal Fabrication factory located in Dongguan, China and specialize in this field since 2011. Our main business is 3D printing service, vacuum casting,CNC machining, plastic injection molding,and sheet matal Fabrication.Own over 200 professional staff and 2300+sets printing devices ,CNC machining center,drilling and milling machine etc.With these machines and experienced employees, we are able to provide strong guarantee for precision and strength parts. we stive to exceed our customer's expectation in all aspects of product manufacturing process, and recognize our great responsiblities to our customers,employees, suppiers and society. we keep adopting advanced production facilities to improve efficiency and ensure high and stable qualtity, and further reduce the production cost. The objective is to create reliable,viable and affordable prototype,plastic and metal parts and fast sample service for every industry

Why Choose YYI Tech

Whether you need new product development verification or personalized customization, YYI Tech can meet your needs

Integrated solution

Integrated solution

One-stop service

One-stop service

Powerful service capability

Powerful service capability

Fast delivery time

Fast delivery time

High quality & Excellent price

High quality & Excellent price

Data confidentiality

Data confidentiality

FAQ