Everything can be printed, and any complex structure can be integrated into one shape

SLM 3D printing service starting at only $14 and MOQ 1pc

How does SLM Metal 3D printing work?

How does SLM metal 3D printing work?

SLM technology is a technology that pre lays the powder and then uses laser rapid melting and rapid cooling to solidify it into shape. During the manufacturing process, it is necessary to use a powder spreader to evenly lay a layer of powder on the substrate in a sealed box, and then use a high-power laser beam to sinter the powder to complete the processing of the layer. Finally, the purpose of manufacturing the sample is achieved by repeating the process and accumulating the number of processing layers.

Advantages of SLM metal 3D printing:

SLM process is highly beneficial for those who need to produce their metal parts for prototyping and simulation, or for low-volume production by eliminating time-consuming tooling.

● Small batches directly produce

Directly driven by 3D design models to produce terminal metal products, eliminating intermediate transition links and saving time for mold opening and manufacturing;

● SLM is suitable for forming various complex shaped workpieces

such as parts with complex internal cavity structures and personalized needs in the medical field, which cannot be manufactured using traditional methods.

● Design verification and functional verification during for product development.

RP technology can quickly convert CAD models of product design into physical fast models, thereby identifying design defects and improving product design. To shorten the research and development cycle and save costs

● Assembly verification.

such as the manufacturability and assembly of satellites, missiles, etc., shall be designed and inspected by RP method. This will greatly reduce the difficulty of designing and manufacturing such systems.

What materials can you choose for SLM prototype 3D printing?

|

Characteristic |

Material |

Material name |

Tolerance |

Max size(mm) |

|

High strength and corrosion resistance |

Aluminum |

AlSi10Mg |

±0.2mm |

400*300*400 |

|

Good casting performance, suitable for printing in thin-walled and complex geometric structures |

Stainless steel |

SUS 316L |

±0.2mm |

250*250*300 |

|

Good mechanical properties, strong corrosion resistance, light weight, and good biocompatibility |

Titanium alloy |

Ti64 |

±0.2mm |

250*250*300 |

|

High strength and toughness, hardness can be 55HRC |

Die steel |

18Ni300 |

±0.2mm |

250*250*300 |

|

Low melting point, high hardness, strong plasticity, wear resistance, corrosion resistance |

Bronze |

|

±0.2mm |

|

Parts Structure Requirements for SLM 3D printing:

If you are new to metal 3D printing technology, please note the following content:

(1) Tapping is recommended for threads, and don't direct printing (including internal and external threads) ;

(2) Wall thickness at least 0.5MM, or it can't be guaranteed to print out

(3) Assembly parts need to be reminded and send assembly drawings. If there is no reminder, we won't assemble them. The gap position should be left each side by 0.15mm;

(4) For parts with high assembly requirements (such as bearing holes/diameters/flat assembly positions), machining allowance should be reserved in advance, and then matched through secondary precision machining;

Surface treatment for 3D printed metal parts:

● Remove support ● Polished ● Painting ● Electroplate

● Water transfer printing ● Sandblasting ● Silk screen ● Laser carving

Case studies of Metal 3D printing:

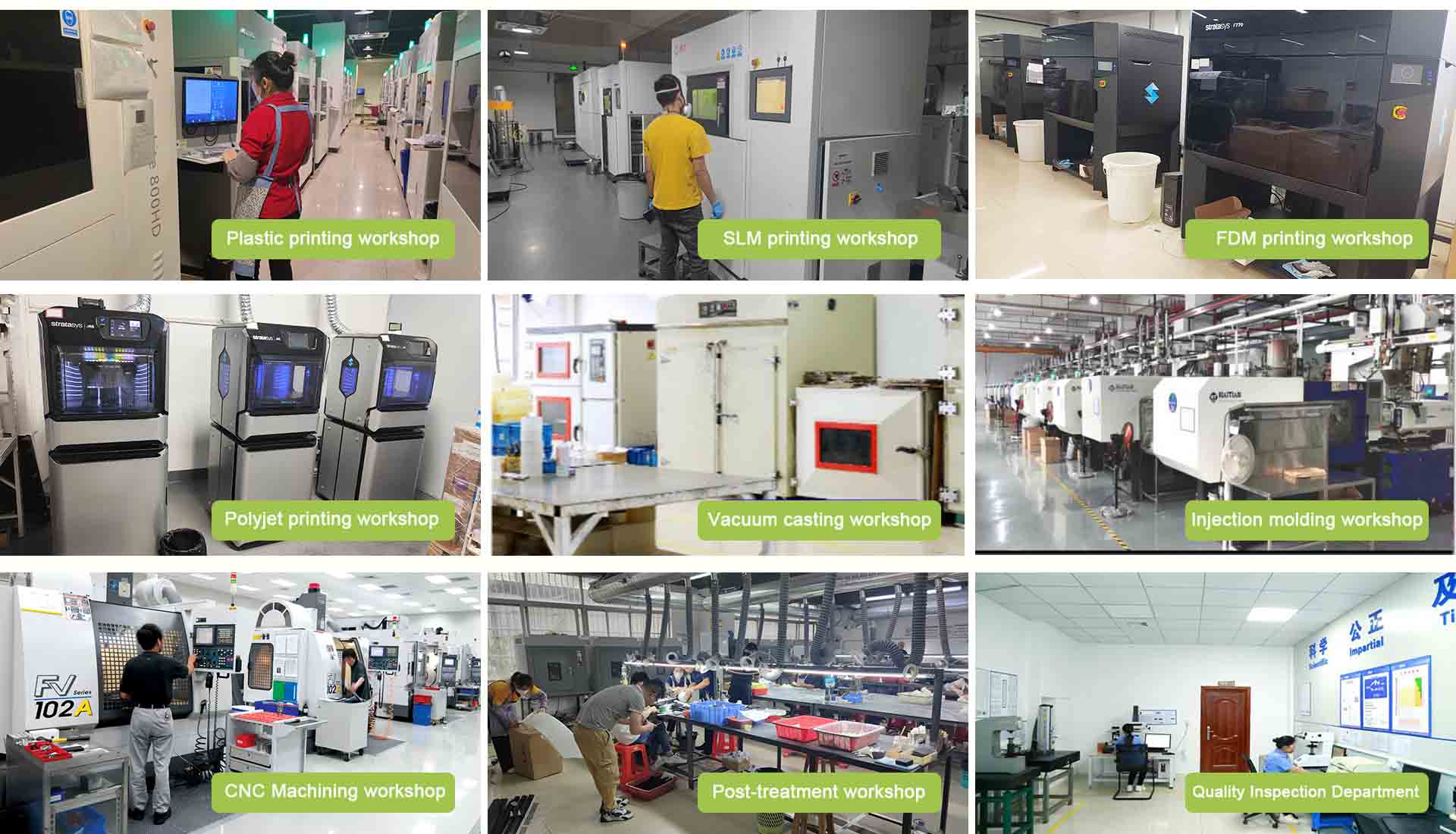

YYI Tech Factory and equipment display

300+sets rapid prototyping equipment, complete materials, complete processes, and comprehensive equipment to meet your various customization needs

About YYI Tech

A professional one-stop rapid prototyping manufacturer

Dongguan Yyi Technology is a professional OEM plastic parts & Metal Fabrication factory located in Dongguan, China and specialize in this field since 2011. Our main business is 3D printing service, vacuum casting,CNC machining, plastic injection molding,and sheet matal Fabrication.Own over 200 professional staff and 2300+sets printing devices ,CNC machining center,drilling and milling machine etc.With these machines and experienced employees, we are able to provide strong guarantee for precision and strength parts. we stive to exceed our customer's expectation in all aspects of product manufacturing process, and recognize our great responsiblities to our customers,employees, suppiers and society. we keep adopting advanced production facilities to improve efficiency and ensure high and stable qualtity, and further reduce the production cost. The objective is to create reliable,viable and affordable prototype,plastic and metal parts and fast sample service for every industry

Why Choose YYI Tech

Whether you need new product development verification or personalized customization, YYI Tech can meet your needs

Integrated solution

Integrated solution

One-stop service

One-stop service

Powerful service capability

Powerful service capability

Fast delivery time

Fast delivery time

High quality & Excellent price

High quality & Excellent price

Data confidentiality

Data confidentiality

FAQ