Customization and small batch production

SLS 3D printing service starting at only $14 and MOQ 1pc

How does SLS Plastic 3D printing work?

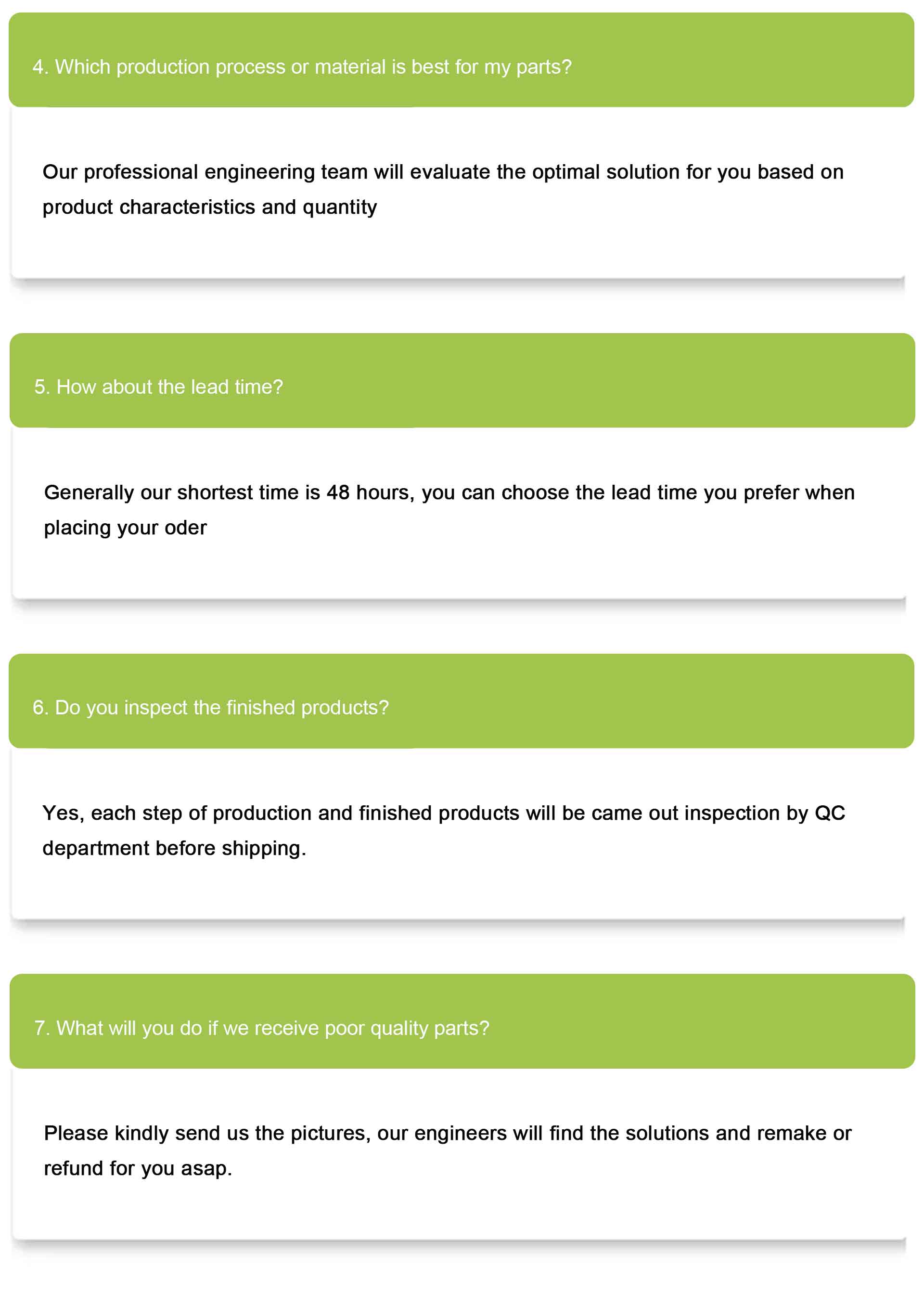

The principle of SLS rapid prototyping:

Using infrared laser sintering powder. First, use a powder roller to lay a layer of powder material, and then irradiate the powder layer with a laser beam to raise the temperature of the irradiated powder above the melting point. Sinter and bond with the formed part below. After a layer is sintered, the printing platform descends by a height of one layer thickness, and the powder laying system lays new powder materials on the printing platform, repeating until the final product is finished.

|

|

| Process diagram | Photofixation process |

Advantages of SLS rapid prototyping:

Due to the excellent performance of processed materials, SLS is a good choice for prototype and small batch production. SLS components are not only increasingly used in prototype designs, but also in mass production applications in many industries. SLS produces parts with high precision and excellent performance, and can achieve printing of parts with complex geometric shapes.

(1) Small batches and special complex parts directly produce, no need mold opening,shorten the production and development cycle and save costs

(2) Tolerance can be ±0.2mm;

(3) SLS no need supporting structure, and the suspended layer that occurs during the stacking process can be directly supported by unsintered powder

(4) SLS process' utilization rate of materials is high. Since no support is required, so no need to add the base

What materials can you choose for SLS plastic 3D printing?

|

Characteristic |

Material |

Material name |

Color |

Tolerance |

Temperature resistance |

|

Surface graininess, high temperature resistance, high strength, suitable for making equipment components such as automotive parts |

Nylon |

PA12 |

White,black |

±0.2mm |

146℃ |

|

White nylon with glass fiber has better strength and higher temperature resistance |

Nylon |

PA Glass-filled |

Off-White,black |

±0.2mm |

162℃ |

Parts Structure Requirements for SLS:

SLS is an innovative and efficient processing method that provides a wide range of possibilities for prototype and small batch production. You can make unlimited modifications to your design, hollowing out thicker areas without affecting the appearance and use, which will help maintain cost reduction and effectively reduce product quality. However, it should be noted that overflow holes should be set up for the uncured material inside the cavity

Case studies of SLS Plastic 3D printing:

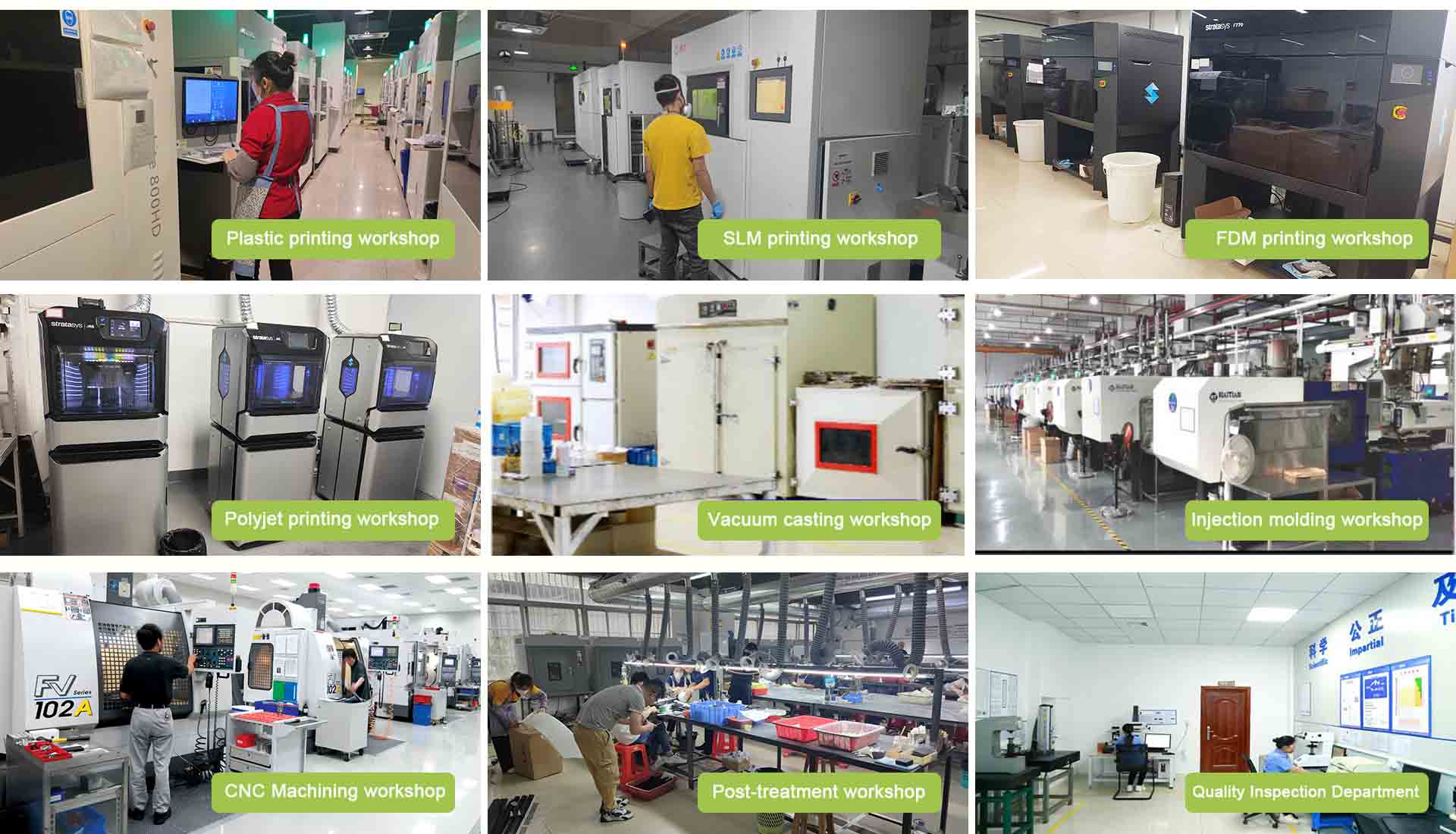

YYI Tech Factory and equipment display

300+sets rapid prototyping equipment, complete materials, complete processes, and comprehensive equipment to meet your various customization needs

About YYI Tech

A professional one-stop rapid prototyping manufacturer

Dongguan Yyi Technology is a professional OEM plastic parts & Metal Fabrication factory located in Dongguan, China and specialize in this field since 2011. Our main business is 3D printing service, vacuum casting,CNC machining, plastic injection molding,and sheet matal Fabrication.Own over 200 professional staff and 2300+sets printing devices ,CNC machining center,drilling and milling machine etc.With these machines and experienced employees, we are able to provide strong guarantee for precision and strength parts. we stive to exceed our customer's expectation in all aspects of product manufacturing process, and recognize our great responsiblities to our customers,employees, suppiers and society. we keep adopting advanced production facilities to improve efficiency and ensure high and stable qualtity, and further reduce the production cost. The objective is to create reliable,viable and affordable prototype,plastic and metal parts and fast sample service for every industry

Why Choose YYI Tech

Whether you need new product development verification or personalized customization, YYI Tech can meet your needs

Integrated solution

Integrated solution

One-stop service

One-stop service

Powerful service capability

Powerful service capability

Fast delivery time

Fast delivery time

High quality & Excellent price

High quality & Excellent price

Data confidentiality

Data confidentiality

FAQ