Small Batch Injection molding

Small Batch Injection molding

YYI tech focuses on rapid prototyping and small batch production manufacturing, providing one-stop services and integrated solutions

As consumers become more fond of the new and tired of the old, brand owners need faster product development iterations; With the development of personalized demand and the Internet, customization has become a market trend. With the diversification and personalization of social demand and the more application of many new materials and new processes, if the traditional mass production and manufacturing method is adopted, not only the cost is high, the productivity is low, but also it is difficult to ensure the quality requirements of products, so we will choose to make several sets of prototype or dozens of sets of small batch to occupy the market first

Small batch plastic product production can use rapid molds,Quick molds are often referred to as soft molds, prototype molds, or transition molds. Rapid mold manufacturing is a crucial step towards the production process, which involves manufacturing a series of tooling molds for producing products, such as rapid injection molds, rapid die-casting molds, sheet metal simple molds, rapid tooling fixtures and jigs, as well as other customized components. Before mass production, manufacturing rapid molds for trial production of hundreds or even thousands of parts is a very useful step for design optimization, functional testing, or pre production validation. For small batch injection molding, using fast molds is very competitive, usually costing 30% -70% of standard steel molds/automatic molds. Rapid mold making has high efficiency and unlimited size.

Advantage of Small batch injection molding :

(1) Quickly obtain small batches of products for consumer testing and market validation;

(2) It can be used as a preliminary experimental model to verify the rationality of mold design and material selection, reducing the risks caused by unreasonable design and manufacturing of mass-produced molds in the later stage;

(3) Realize fast and customized production in small batches

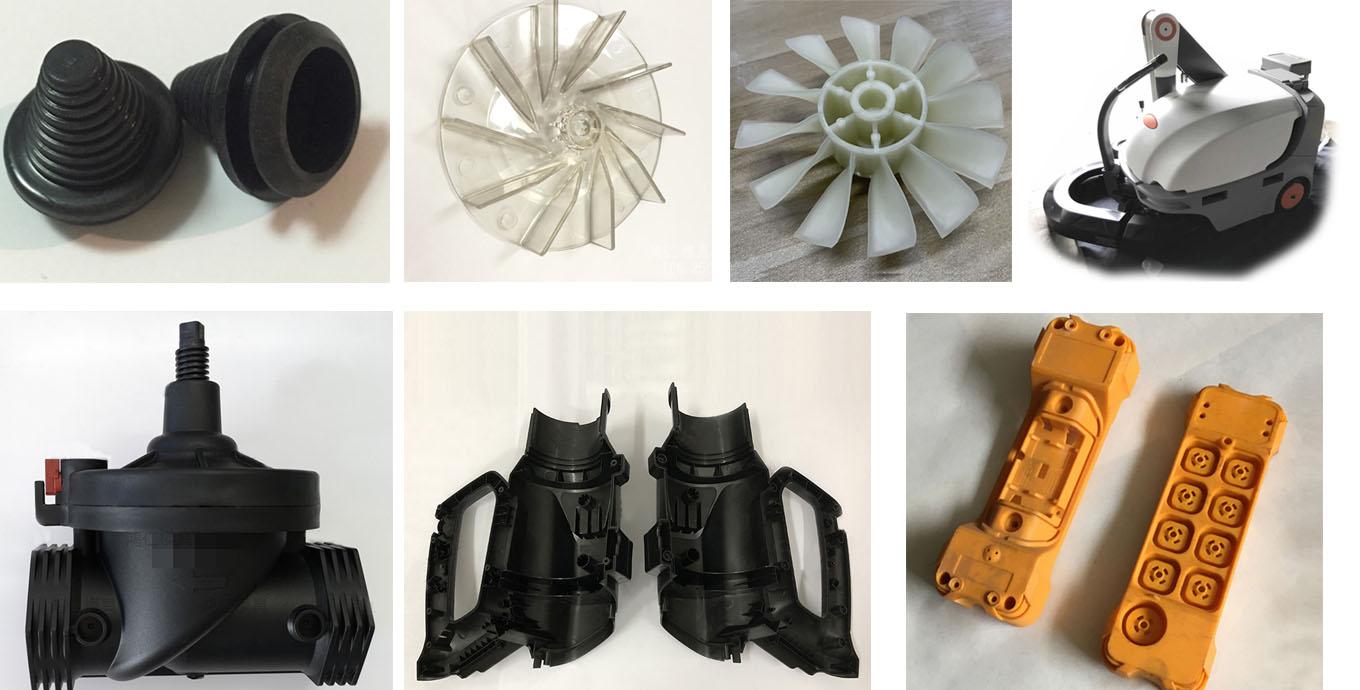

Applications of Small batch injection molding:

Computer and server decoration

Electronic plastic parts

Medical plastic parts

Industrial plastic accessories