Combining various rapid prototyping processes and rapid molding to provide small batch production services,mainly including industrial 3D printing,vacuum casting,injection molding,Reaction Injection Moulding(RIM),CNC Machining,etc.

By flexibly utilizing various rapid prototype processes, providing integrated solutions and one-stop services, to achieve theoptimal quality, optimal price, and optimal delivery time

Small batch plastic & metal parts

YYI tech is a professional manufacturer that provides small batch services. We are a leader in the industry in solving production and manufacturing solutions. Our team can provide the best solutions by integrating materials, processes, etc

What's Small volume manufacturing:

Small batch manufacturing is a professional and rapid production service that provides the parts of full materials, full production process, and the same quality as large batches, but with quantities ranging from single pieces to thousands of pieces.

When need Small volume manufacturing:

(1) Before launches a product in large quantities, it generally needs to conduct small-scale production for market response verification. This is a very useful step for design optimization, functional testing, or pre production verification. Small batch prototype processing can ensure that the product is displayed in various markets and sales channels while avoiding the high cost risk of mold opening.

(2) There are prototypes that require sample testing, as well as prototypes that replace products for customers. Nowadays, many professional industry products do not have a large final mass production quantity. If you have to open a set of molds that can cost tens or millions of dollars for dozens or hundreds of products, the cost is too high. So in this case, a reliable prototype manufacturer is needed to customize the product through prototype customization. Although the unit price of the product is relatively high, there is no need for mold fees. In the end, if the quantity is not large, the cost-effectiveness of making small batches is the highest.

Advantages of Small volume manufacturing:

SLM process is highly beneficial for those who need to produce their metal parts for prototyping and simulation, or for low-volume production by eliminating time-consuming tooling.

● Short cycle

For small-scale prototype customization, Making a silicone mold or low-pressure injection mold takes only two or three days, and for complex ones, it only takes one week to start production.

● Low price

If the production quantity of the product is only a few dozen to a thousand, the high mold cost will be very uneconomical. In this case, the price will be much lower through small batch customization of prototypes

● Flexible product upgrade

Once the mold is opened, want to upgrade the appearance or change the product structure, you need to modify the mold or even create a new set of molds, which invisibly increases a lot of time and cost. However, there is no such problem with small batch customization of prototypes. The molds for small batch customization of prototypes are cheap and the cycle is short. If the product needs to be modified. We can help you complete product upgrades at a very low cost within just one week.

Process of Low volume manufacturing serive:

|

Process |

Available Material |

Tolerance |

Characteristic |

|

3D printing |

Resin,ABS,Nylon,TPU,Peek, Stainless steel,Aluminum,Titanium |

±0.1mm ~ ±0.2mm |

No MOQ,no mold fee,complex structures can be produced |

|

Urethane casting |

ABS,Nylon,POM, PC, TPU, |

±0.3mm |

Need simple mold, mold cost is low,mold time is 3-7days, suitable for 10-200pcs plastic parts |

|

Plastic injection molding |

ABS,Nylon,POM, PP, TPU,PMMA,Peek,PE,etc |

±0.2mm |

Need simple mold, mold cost is low,good structural strength, and minimal deformation |

|

CNC machining |

Stainless steel,Aluminum,Titanium,Copper |

±0.1mm |

No MOQ,no mold fee,complex structures can be produced |

|

Sheet metal fabrication |

Aluminum, brass, copper,steel,stainless steel |

±0.2mm |

No MOQ,no mold fee,complex structures can be produced |

Case studies of Low-volume manufacturing:

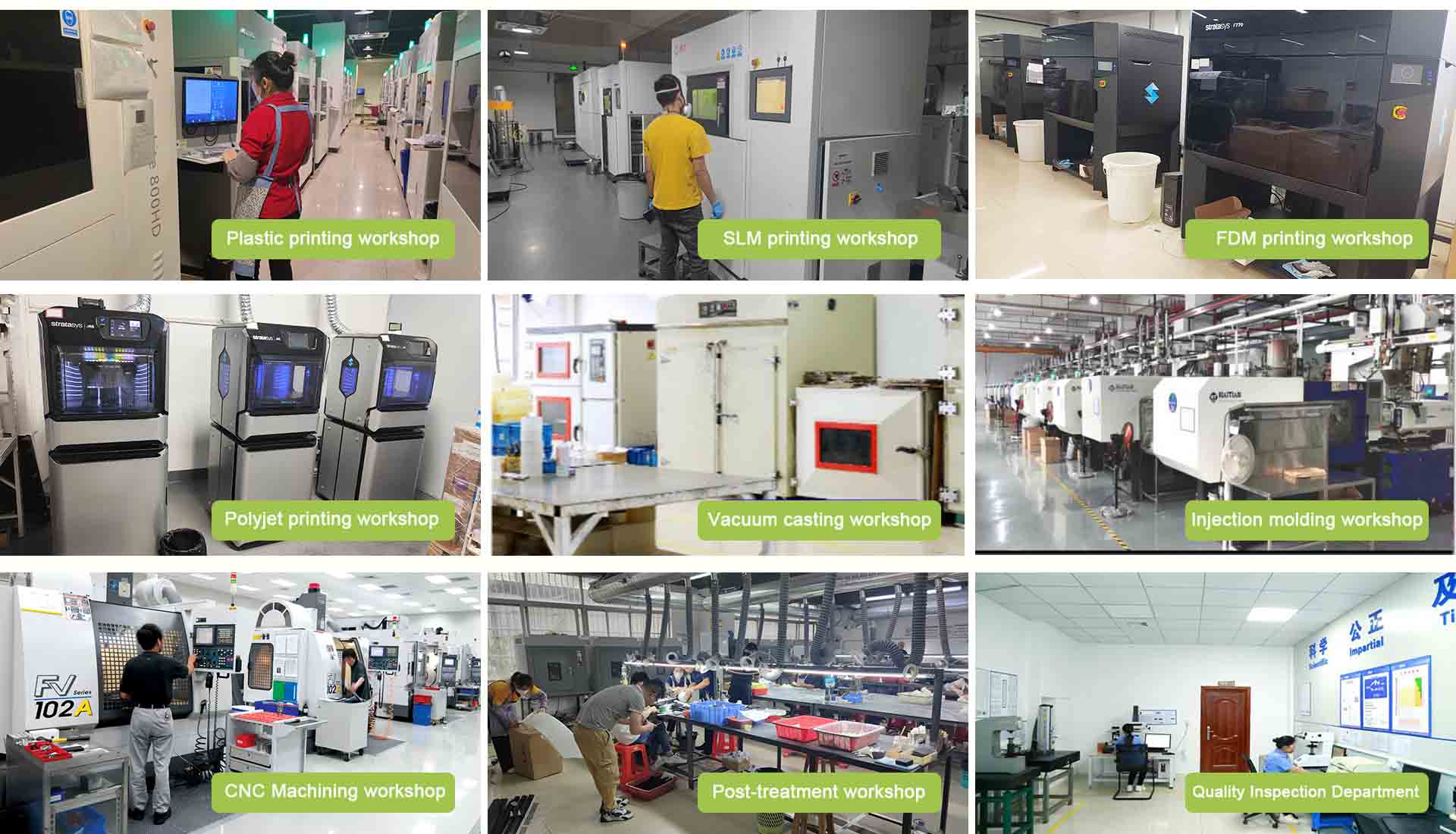

YYI Tech Factory and equipment display

300+sets rapid prototyping equipment, complete materials, complete processes, and comprehensive equipment to meet your various customization needs

About YYI Tech

A professional one-stop rapid prototyping manufacturer

Dongguan Yyi Technology is a professional OEM plastic parts & Metal Fabrication factory located in Dongguan, China and specialize in this field since 2011. Our main business is 3D printing service, vacuum casting,CNC machining, plastic injection molding,and sheet matal Fabrication.Own over 200 professional staff and 2300+sets printing devices ,CNC machining center,drilling and milling machine etc.With these machines and experienced employees, we are able to provide strong guarantee for precision and strength parts. we stive to exceed our customer's expectation in all aspects of product manufacturing process, and recognize our great responsiblities to our customers,employees, suppiers and society. we keep adopting advanced production facilities to improve efficiency and ensure high and stable qualtity, and further reduce the production cost. The objective is to create reliable,viable and affordable prototype,plastic and metal parts and fast sample service for every industry

Why Choose YYI Tech

Whether you need new product development verification or personalized customization, YYI Tech can meet your needs

Integrated solution

Integrated solution

One-stop service

One-stop service

Powerful service capability

Powerful service capability

Fast delivery time

Fast delivery time

High quality & Excellent price

High quality & Excellent price

Data confidentiality

Data confidentiality

FAQ