Provide various post-treatment processes such as heat treatment, polishing and grinding, painting, electroplating, etc. according to your needs

Surface Post Processing

After the rapid prototyping accessories are produced, they need to be post-processing, and only after post-processing can the parts be closer to the designed finished product. There are many post-processing techniques, and there are differences between metal and plastic parts. various post-processing processes such as heat treatment, polishing, painting, electroplating, etc. can be used to improve and strengthen the various properties of the parts. YYI TECH's supply chain system has a large number of professional engineers and post-processing technicians, who will provide one-stop comprehensive solutions according to your needs.

The role of surface treatment:

In order to remove various foreign objects (such as oil stains, rust, dust, old paint films, etc.) attached to the surface of objects, provide a good substrate suitable for painting requirements, and ensure that the coating has good anti-corrosion performance, decorative performance, and certain special functions, the surface of the object must be pre treated before painting. People refer to the work done for this treatment as pre coating (surface) treatment or (surface) pretreatment.

During the processing, transportation, and storage of workpieces, the surface often contains oxide scales, rust, mold residue, welding slag, dust, oil, and other contaminants. To ensure that the coating can firmly adhere to the surface of the workpiece, the workpiece surface must be cleaned before painting. Otherwise, it not only affects the adhesion and corrosion resistance between the coating and the metal, but also allows the base metal to continue to corrode even with coating protection, causing the coating to peel off and affecting the mechanical properties and service life of the workpiece. Therefore, surface treatment before painting the workpiece is an important guarantee and measure to obtain a high-quality protective layer and extend the service life of the product.

Post-processing Treatment Type

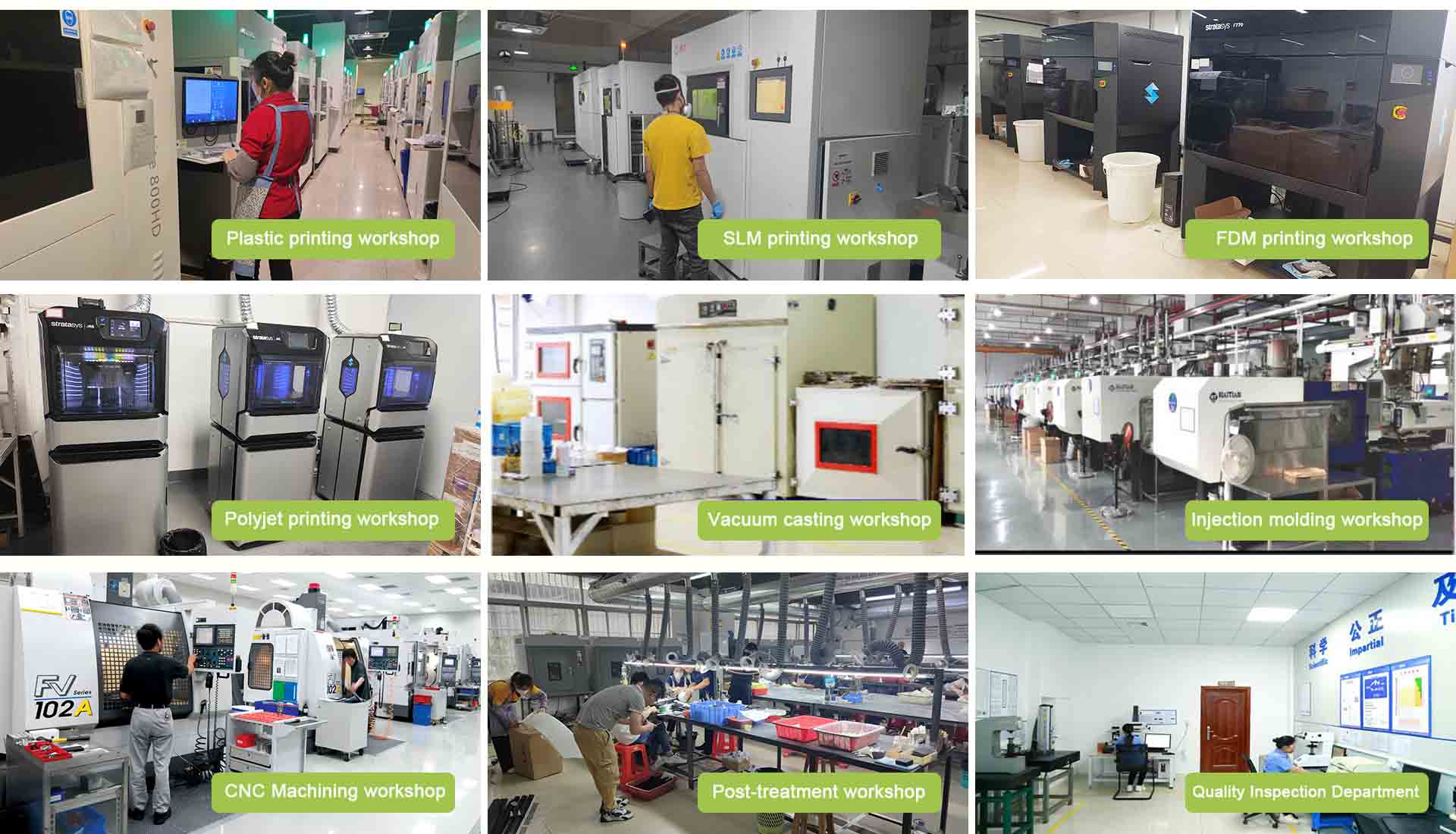

YYI Tech Factory and equipment display

300+sets rapid prototyping equipment, complete materials, complete processes, and comprehensive equipment to meet your various customization needs

About YYI Tech

A professional one-stop rapid prototyping manufacturer

Dongguan Yyi Technology is a professional OEM plastic parts & Metal Fabrication factory located in Dongguan, China and specialize in this field since 2011. Our main business is 3D printing service, vacuum casting,CNC machining, plastic injection molding,and sheet matal Fabrication.Own over 200 professional staff and 2300+sets printing devices ,CNC machining center,drilling and milling machine etc.With these machines and experienced employees, we are able to provide strong guarantee for precision and strength parts. we stive to exceed our customer's expectation in all aspects of product manufacturing process, and recognize our great responsiblities to our customers,employees, suppiers and society. we keep adopting advanced production facilities to improve efficiency and ensure high and stable qualtity, and further reduce the production cost. The objective is to create reliable,viable and affordable prototype,plastic and metal parts and fast sample service for every industry

Why Choose YYI Tech

Whether you need new product development verification or personalized customization, YYI Tech can meet your needs

Integrated solution

Integrated solution

One-stop service

One-stop service

Powerful service capability

Powerful service capability

Fast delivery time

Fast delivery time

High quality & Excellent price

High quality & Excellent price

Data confidentiality

Data confidentiality

FAQ