Fused Deposition Modeling (FDM) has become a cornerstone of modern manufacturing and innovation. Its affordability, versatility, and compatibility with various materials make it a go-to technology for businesses across diverse industries. From prototyping to functional parts production, FDM is reshaping how industries approach design and manufacturing. In this article, we explore the key industries leveraging FDM 3D printing and the transformative impact it brings.

Applications:

Benefits:

FDM accelerates the design-to-production cycle, reduces costs, and enables on-the-fly adjustments, making it invaluable for engineering and manufacturing processes.

Applications:

Benefits:

FDM's ability to print with high-performance materials like ULTEM™ or PEEK makes it ideal for parts that must withstand extreme conditions, including high stress and temperatures.

Applications:

Benefits:

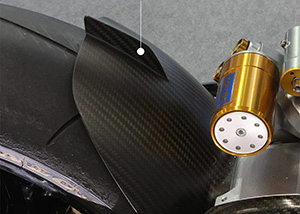

FDM helps automotive manufacturers save time and resources, enabling faster prototyping and production of durable, high-quality parts.

Applications:

Benefits:

FDM supports biocompatible materials for safe and effective medical applications, while its customization capabilities improve patient-specific solutions.

Applications:

Benefits:

Affordable and easy to operate, FDM printers provide students and researchers with the tools to innovate and experiment with real-world applications.

Applications:

Benefits:

FDM empowers designers to test and refine their ideas efficiently, reducing time-to-market for innovative consumer products.

Applications:

Benefits:

FDM simplifies the creation of detailed architectural models, enabling architects to communicate their designs effectively to clients and stakeholders.

Applications:

Benefits:

With its ability to print intricate designs in various materials, FDM opens new possibilities for artists and designers to bring their visions to life.

Applications:

Benefits:

FDM’s speed and flexibility allow military organizations to quickly produce on-demand solutions for field operations and training scenarios.

Applications:

Benefits:

FDM’s precision and material options make it suitable for creating tailored solutions for the food industry.

The adaptability of FDM technology stems from its wide material compatibility, including PLA, ABS, PETG, and specialty materials like carbon-fiber composites. This versatility ensures FDM meets the needs of applications ranging from lightweight, high-strength aerospace components to flexible, custom medical devices.

At [Your Company Name], we specialize in providing tailored FDM 3D printing services to help businesses across industries innovate and achieve their goals. Whether you're prototyping a new design, creating custom tools, or producing functional parts, our team is here to guide you through the process.

FDM 3D printing continues to disrupt traditional manufacturing, offering unprecedented flexibility and cost savings. From engineering to healthcare, its impact spans a wide array of industries. Ready to bring your ideas to life? Contact us today to learn more about our FDM 3D printing solutions and how they can benefit your business.