Processing method: compound mold

Material: ABS,Nylon,POM,PP

Surface treatment: deburring

Processing cycle: 3-7 working days

Testing standard: Customer provides 3D drawings

Data format: STP/IGS/STEP

Vacuum casting Hard Plastic Parts

The principle of Vacuum casting:

Using 3D printing or CNC processing to produce prototype parts of the product, a silicone mold is made in vacuum state, and materials such as PU, transparent PU, POM like, ABS are used for pouring in vacuum state to replicate the same replica as the prototype part

Available Material of Hard Plastic Vacuum Casting:

| Material | Color | Temperature resistance | Characteristic |

| ABS | Beige/Black/White | 70-80℃ | Good mechanical properties similar to ABS thermoplastic materials |

| Flame-retardant ABS | Black/White | 60-70℃ | Flame retardant materials with fire resistance requirements and mechanical properties similar to ABS |

| PP | Black/White | About 70℃ | High impact strength, high fracture elongation, and excellent flexibility |

| Nylon | Black/White | 120℃,heat treament 150℃ | High temperature resistance, corrosion resistance, acid and alkali resistance, good hardness and strength, and good wear resistance |

| POM | White | 120℃ | Good impact strength, similar to thermoplastic POM |

Application of Vacuum casting service:

In the process of making prototype, sometimes customers may need to make small batches. If use CNC processing, the cost will be relatively high. At this time, silicone vacuum casting can be used. Robotic silicone vacuum casting is quite common in daily production because customers usually use this type of prototype to make products, and the quantity produced is not too small. In this case, using vacuum casting is more reasonable, which can help enterprises reduce costs and save time.

Small Batch Robot silicone Vacuum Casting - Low Cost

This is a robot silicone vacuum casting project that YYI TECH has done. Due to the limited budget of the customer, we recommend using silicone vacuum casting for processing. Moreover, for products like robots, if the mold is opened recklessly, the losses caused by the project failure will be very significant. Therefore, in order to reduce risks, it is better to adopt a prudent approach. This project mainly involves the following steps:

1. Creating prototypes

Create a prototype through 3D printing or CNC machining. Due to the large size of the robot and the high cost of 3D printing, CNC machining is used here.

2. Making silicone molds

After completing the prototype, use it to make a silicone mold. Due to the impact of thermal expansion and contraction on the products produced by the robot silicone re molding, the silicone mold is generally made slightly larger. After cooling, it can reach the size desired by the customer.

3. Silicone mold replication

After finished the silicone mold, we can use it for replication. Due to the deformation of the mold during the production process, generally one mold can only produce 15pcs parts

4.Remove the silicone mold

After the robot completes the silicone re molding step, the mold can be cut open to remove the workpiece inside.

More Application of Hard Plastic Vacuum casting service:

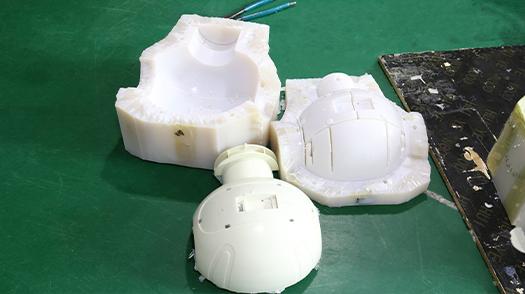

YYI Tech Factory and equipment display

300+sets rapid prototyping equipment, complete materials, complete processes, and comprehensive equipment to meet your various customization needs

About YYI Tech

A professional one-stop rapid prototyping manufacturer

Dongguan Yyi Technology is a professional OEM plastic parts & Metal Fabrication factory located in Dongguan, China and specialize in this field since 2011. Our main business is 3D printing service, vacuum casting,CNC machining, plastic injection molding,and sheet matal Fabrication.Own over 200 professional staff and 2300+sets printing devices ,CNC machining center,drilling and milling machine etc.With these machines and experienced employees, we are able to provide strong guarantee for precision and strength parts. we stive to exceed our customer's expectation in all aspects of product manufacturing process, and recognize our great responsiblities to our customers,employees, suppiers and society. we keep adopting advanced production facilities to improve efficiency and ensure high and stable qualtity, and further reduce the production cost. The objective is to create reliable,viable and affordable prototype,plastic and metal parts and fast sample service for every industry

Why Choose YYI Tech

Whether you need new product development verification or personalized customization, YYI Tech can meet your needs

Integrated solution

Integrated solution

One-stop service

One-stop service

Powerful service capability

Powerful service capability

Fast delivery time

Fast delivery time

High quality & Excellent price

High quality & Excellent price

Data confidentiality

Data confidentiality

FAQ