Processing method: compound mold

Material: TPU

Surface treatment: deburring/polishing/painting

Processing cycle: 3-7 working days

Testing standard: Customer provides 3D drawings

Data format: STP/IGS/STEP/STL

Vacuum casting Soft Plastic Parts

The principle of Vacuum casting:

Using 3D printing or CNC processing to produce prototype parts of the product, a silicone mold is made in vacuum state, and materials such as PU, transparent PU, POM like, ABS are used for pouring in vacuum state to replicate the same replica as the prototype part

Available Material of Soft Plastic Vacuum Casting:

| Material | Color | Hardness | Temperature resistance |

| TPU | Translucent/Black/White | Shore A 30-90 | 100℃ |

Advantage of Vacuum casting service:

Directly transforming design products into model samples, it only takes one week from creative development to sample creation. The application of prototype production in exhibition series products and foreign trade products has unparalleled effectiveness in quickly responding to orders and avoiding changes in mold development. The use of rapid modeling techniques can fully and intuitively express the appearance and structure of a product, just like printing out a three-dimensional diagram, so that problems can be discovered during the design phase and defects can be avoided.

Application of Soft Plastic Vacuum casting:

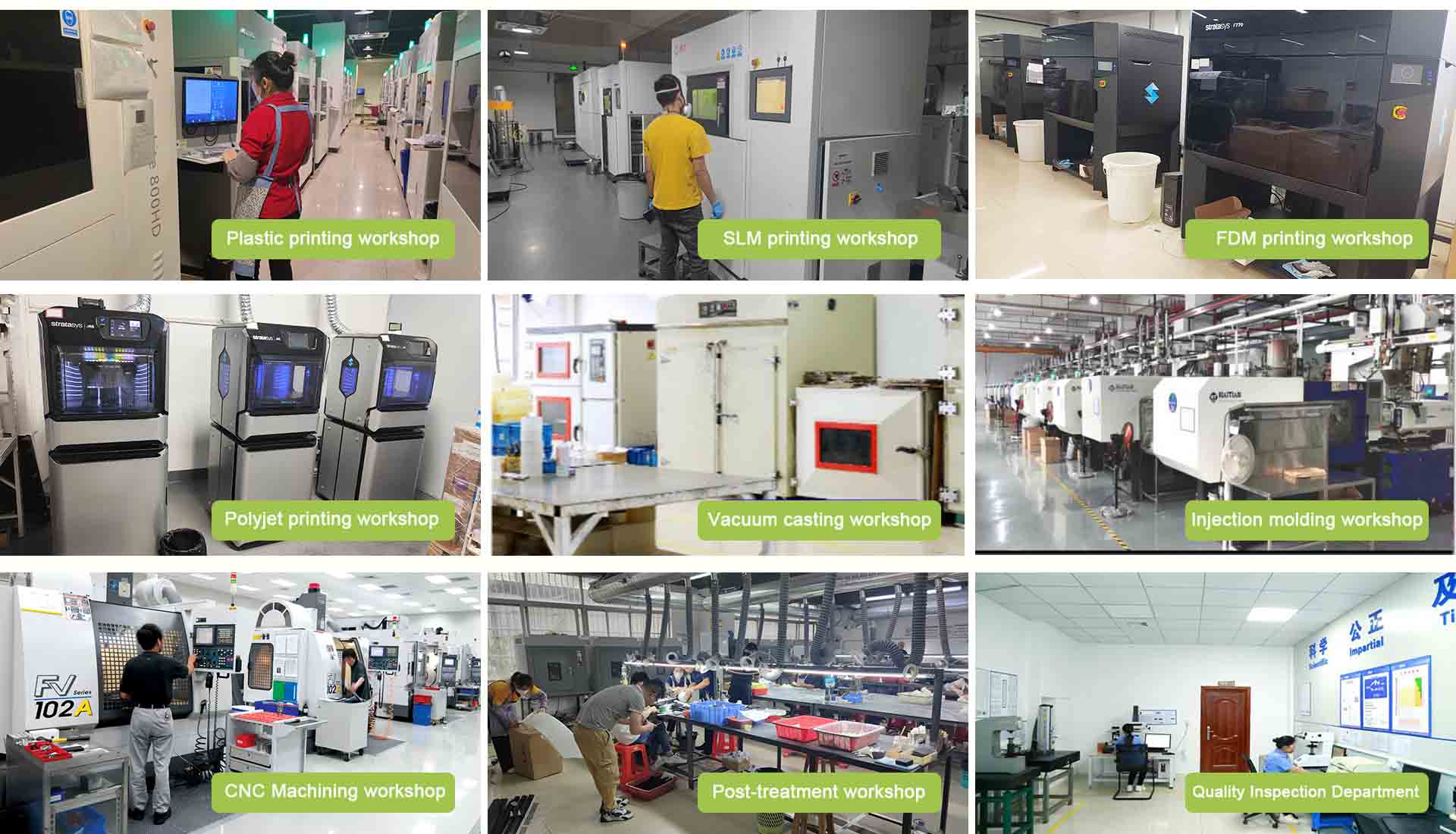

YYI Tech Factory and equipment display

300+sets rapid prototyping equipment, complete materials, complete processes, and comprehensive equipment to meet your various customization needs

About YYI Tech

A professional one-stop rapid prototyping manufacturer

Dongguan Yyi Technology is a professional OEM plastic parts & Metal Fabrication factory located in Dongguan, China and specialize in this field since 2011. Our main business is 3D printing service, vacuum casting,CNC machining, plastic injection molding,and sheet matal Fabrication.Own over 200 professional staff and 2300+sets printing devices ,CNC machining center,drilling and milling machine etc.With these machines and experienced employees, we are able to provide strong guarantee for precision and strength parts. we stive to exceed our customer's expectation in all aspects of product manufacturing process, and recognize our great responsiblities to our customers,employees, suppiers and society. we keep adopting advanced production facilities to improve efficiency and ensure high and stable qualtity, and further reduce the production cost. The objective is to create reliable,viable and affordable prototype,plastic and metal parts and fast sample service for every industry

Why Choose YYI Tech

Whether you need new product development verification or personalized customization, YYI Tech can meet your needs

Integrated solution

Integrated solution

One-stop service

One-stop service

Powerful service capability

Powerful service capability

Fast delivery time

Fast delivery time

High quality & Excellent price

High quality & Excellent price

Data confidentiality

Data confidentiality

FAQ