Processing method: compound mold

Material: PC/Acrylic

Surface treatment: deburring

Processing cycle: 3-7 working days

Testing standard: Customer provides 3D drawings

Data format: STP/IGS/X.T/PRO

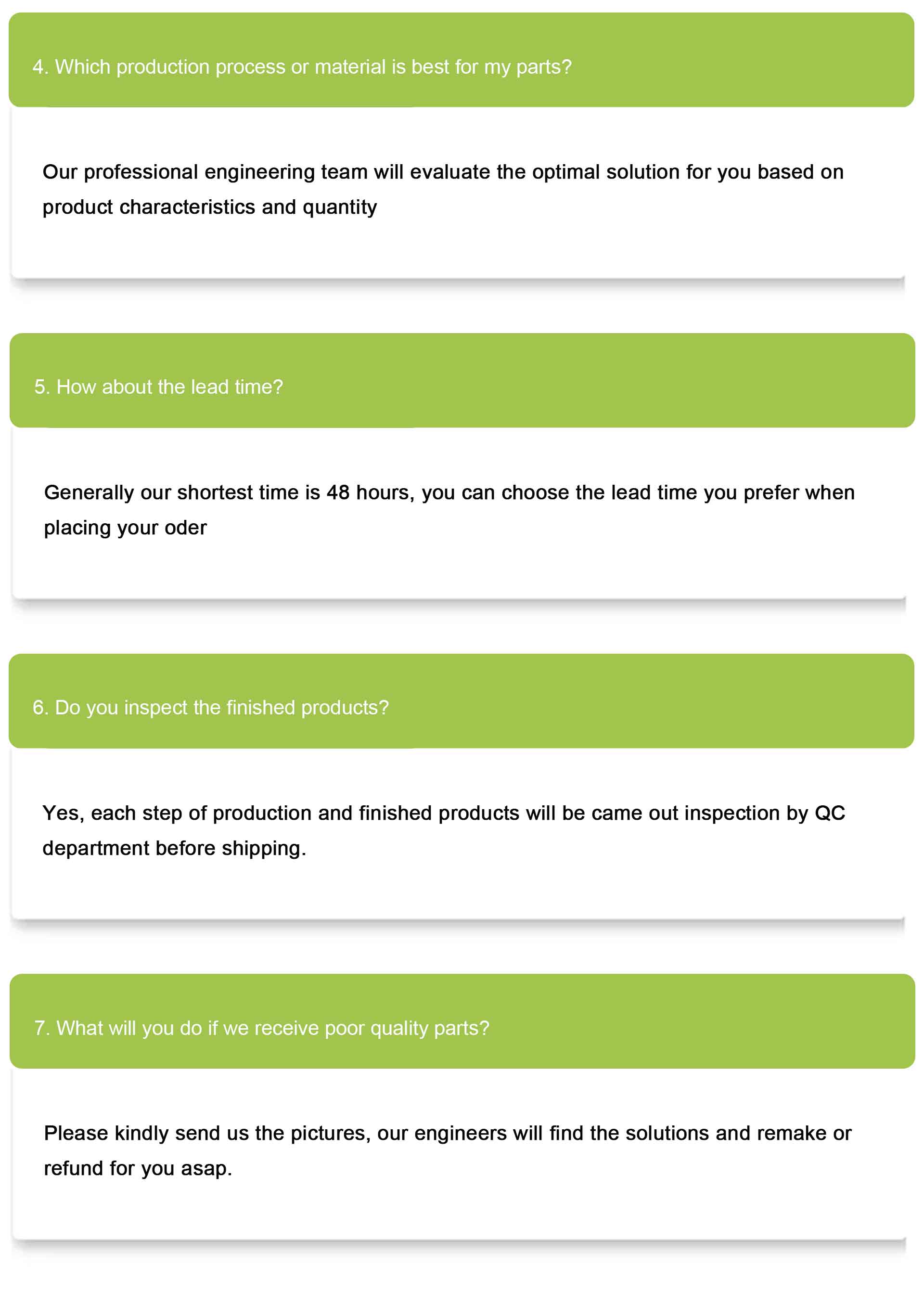

Vacuum casting transparent parts

The principle of Vacuum casting:

Vacuum cating is a manual manufacturing method that uses prototype parts processed by CNC or SLA to quickly and inexpensively produce silicone molds. The material used is liquid PU. Depending on the complexity of the components, each silicone mold can produce 15 to 25 products. Due to the small batch production required for this scorer prototype, a vacuum casting method was adopted

Transparent Power battery box Vacuum casting service

Automotive transparent lampshade prototype

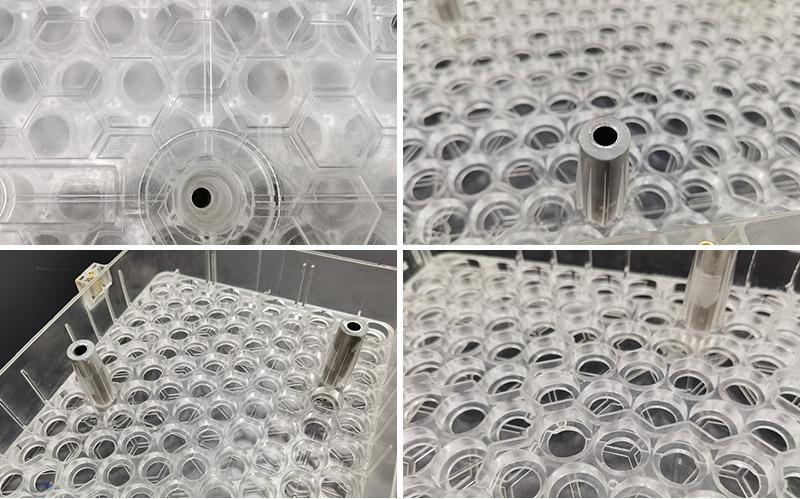

The above are the transparent parts we have made for the customer. They need to order 80pcs, and considering the high cost of other process, so we suggest vacuum casting to produce it. First, we needed to make a prototype, then use this prototype to make a silicone mold, and then use this silicone mold for batch replication. Due to the fact that only about 20 silicone molds can be replicated, we need to make a total of 4 silicone molds. The following is the production process of the prototype:

Process of Vacuum casting:

1.Use CNC, SLA, or clay carving to create prototypes and make water outlets.

2.Surround the prototype with a board to prepare for mold making.

3.Pour the liquid silicone that has been vacuumed using a vacuum machine into the mold and cover the entire product.

4.Put the mold into the oven for baking, so that the silicone mold can accelerate the curing process.

5.Remove the prototype from the mold.

6.According to the materials required for the product, some finished products are replicated by vacuum pouring.

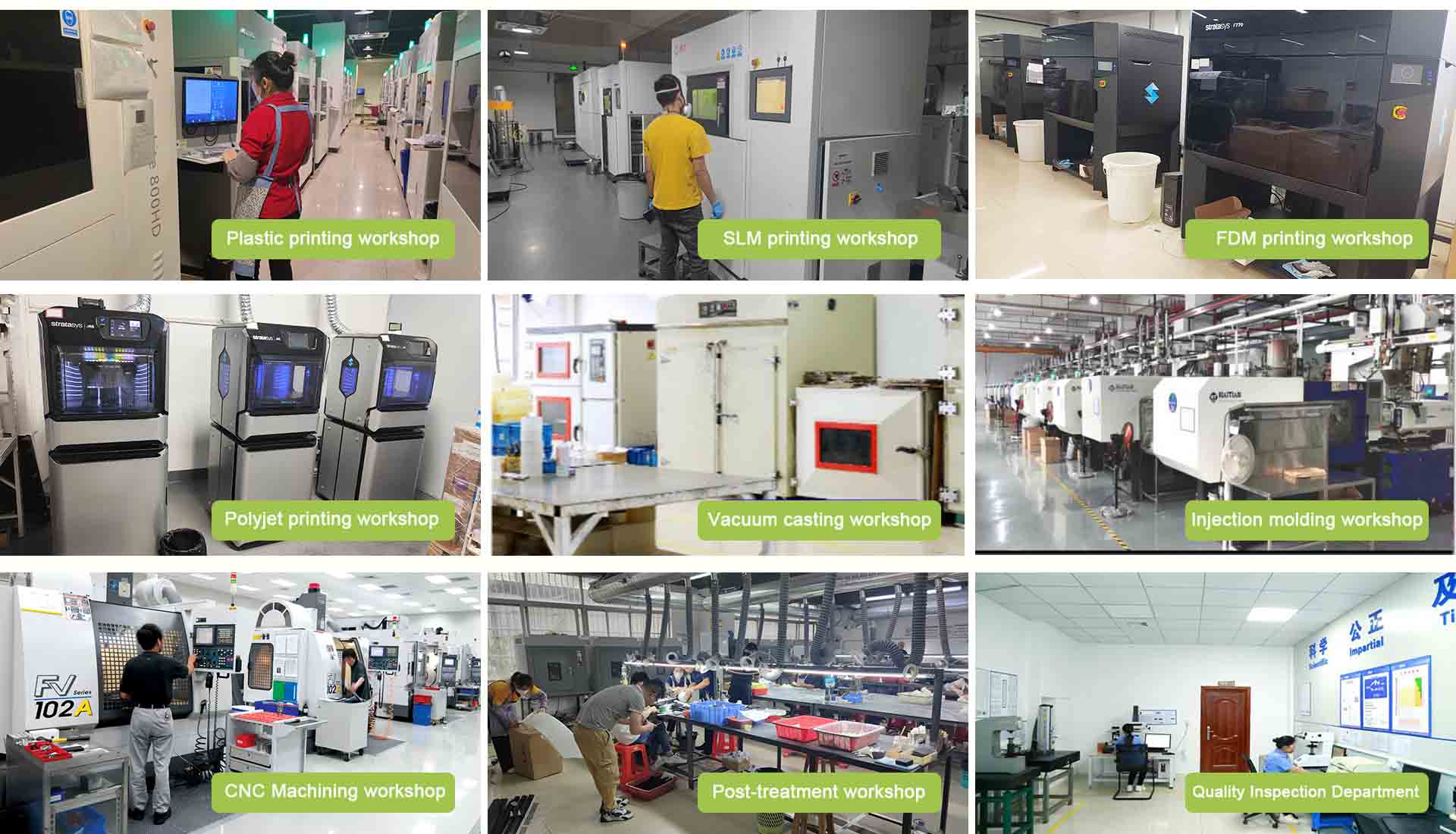

YYI Tech Factory and equipment display

300+sets rapid prototyping equipment, complete materials, complete processes, and comprehensive equipment to meet your various customization needs

About YYI Tech

A professional one-stop rapid prototyping manufacturer

Dongguan Yyi Technology is a professional OEM plastic parts & Metal Fabrication factory located in Dongguan, China and specialize in this field since 2011. Our main business is 3D printing service, vacuum casting,CNC machining, plastic injection molding,and sheet matal Fabrication.Own over 200 professional staff and 2300+sets printing devices ,CNC machining center,drilling and milling machine etc.With these machines and experienced employees, we are able to provide strong guarantee for precision and strength parts. we stive to exceed our customer's expectation in all aspects of product manufacturing process, and recognize our great responsiblities to our customers,employees, suppiers and society. we keep adopting advanced production facilities to improve efficiency and ensure high and stable qualtity, and further reduce the production cost. The objective is to create reliable,viable and affordable prototype,plastic and metal parts and fast sample service for every industry

Why Choose YYI Tech

Whether you need new product development verification or personalized customization, YYI Tech can meet your needs

Integrated solution

Integrated solution

One-stop service

One-stop service

Powerful service capability

Powerful service capability

Fast delivery time

Fast delivery time

High quality & Excellent price

High quality & Excellent price

Data confidentiality

Data confidentiality

FAQ